- Joined

- Nov 5, 2016

- Messages

- 1,419

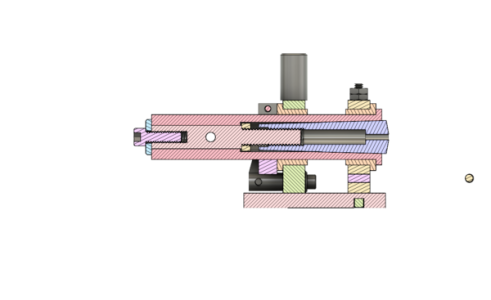

Yes I did. I also made it to fit my Morse taper #2 collets I already had. It might be tricky working on the sides of long end mill though since I might run out of twist on my wrist pulling it through! I can't use two hand since one is holding the fixture in place. In his videos Harold uses his advanced grinding fixture which has a screw/clamp to hold the fixture in place which is a big plus. If I like the simple rest as much as I think I'm going to I may very well make the advanced one too later on.

I agree from the pictures Harold seems to use stubby cutters.

For the front support I actually made a short one (shorter than Harold's drawings) and then two screw on extensions. I figured that was easier than making two or three individual complete arms. I need a pretty long one if I use the full length of the spindle, but shorter ones are needed for shorter lengths.

Ted

I agree from the pictures Harold seems to use stubby cutters.

For the front support I actually made a short one (shorter than Harold's drawings) and then two screw on extensions. I figured that was easier than making two or three individual complete arms. I need a pretty long one if I use the full length of the spindle, but shorter ones are needed for shorter lengths.

Ted