- Joined

- Nov 2, 2012

- Messages

- 415

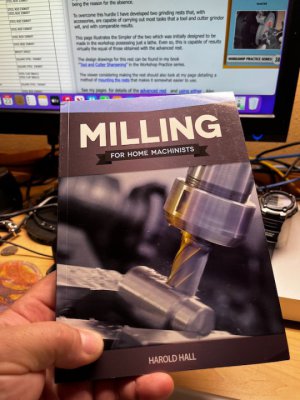

Hey all, long time since I posted. Kind of got away from machining the last few years, but decided to get crackin' on some projects that I hadn't finished. If you haven't read any of the Workshop Practice Series books, I highly recommend them. Harold Hall is my favorite of the authors, and he also has some other books to his credit where he takes you through lathe or mill projects that start fairly simple and progress in difficulty to build skills, and you use the earlier tools to create the later ones. I skipped most of the projects, but I completed the knurling tool and the boring head so far.

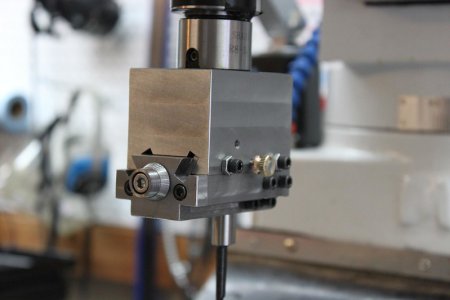

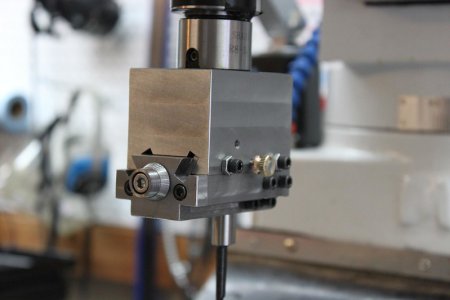

Boring head:

The plans are mostly in metric, but I have been converting things to imperial like fasteners and screws for measurement. It gets a bit dicey here and there for fasteners if you aren't careful, but so far so good.

I replaced the brass wheel with a socket head because this iteration took too much effort, even though keyless was nice.

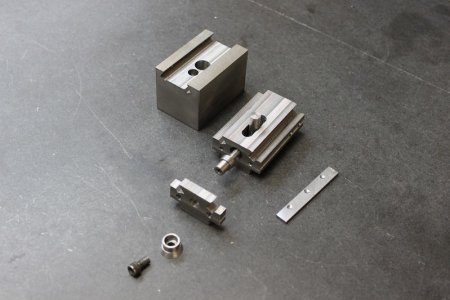

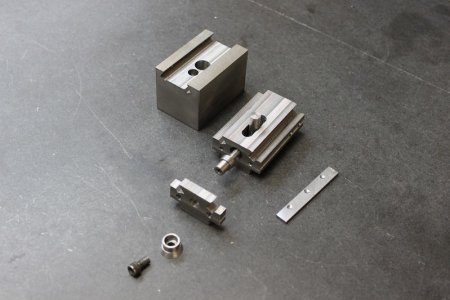

Knurling tool:

I'm aware that the knurling wheel retaining screws are unsightly, but my local hardware doesn't stock M3 so I'll order some when I order hardware for other projects. I also made a longer clamping bolt after this photo was taken to allow the jaws to open a bit wider.

I'm presently working on Mr. Hall's Advanced Grinder Rest. I'm further than pictured here, but haven't taken any recent photos. I also think I botched a part or two that I may need to remake - not going to act like I'm perfect.

Grinder rest:

I'll need to make a base for this tool and grinder to mount to, and there are a couple of accessories he designed for use with the rest that I have stock for. Once this one is done (or at least mostly done), I'll be making his Lining Tool for marking out graduated dials in a more consistent and controlled manner. The design is shown for Imperial marking, but has an alternative couple of parts one can make if a fella prefers working in metric.

Anyhow, I just thought I'd share. I haven't used the knurling tool much more than on its own knob, but it feels pretty solid. The boring head is excellent.

His website has a ton of projects and information, but I think you need to buy the books for these particular projects. Fair enough.

Boring head:

The plans are mostly in metric, but I have been converting things to imperial like fasteners and screws for measurement. It gets a bit dicey here and there for fasteners if you aren't careful, but so far so good.

I replaced the brass wheel with a socket head because this iteration took too much effort, even though keyless was nice.

Knurling tool:

I'm aware that the knurling wheel retaining screws are unsightly, but my local hardware doesn't stock M3 so I'll order some when I order hardware for other projects. I also made a longer clamping bolt after this photo was taken to allow the jaws to open a bit wider.

I'm presently working on Mr. Hall's Advanced Grinder Rest. I'm further than pictured here, but haven't taken any recent photos. I also think I botched a part or two that I may need to remake - not going to act like I'm perfect.

Grinder rest:

I'll need to make a base for this tool and grinder to mount to, and there are a couple of accessories he designed for use with the rest that I have stock for. Once this one is done (or at least mostly done), I'll be making his Lining Tool for marking out graduated dials in a more consistent and controlled manner. The design is shown for Imperial marking, but has an alternative couple of parts one can make if a fella prefers working in metric.

Anyhow, I just thought I'd share. I haven't used the knurling tool much more than on its own knob, but it feels pretty solid. The boring head is excellent.

His website has a ton of projects and information, but I think you need to buy the books for these particular projects. Fair enough.