- Joined

- Dec 28, 2022

- Messages

- 253

How in the heck do you guys drain the oil from your headstock’s without getting oil all over the stinkin place? Also, anyone have tips on getting oil INTO the gearbox faster than a 1/4” tube on a small funnel?

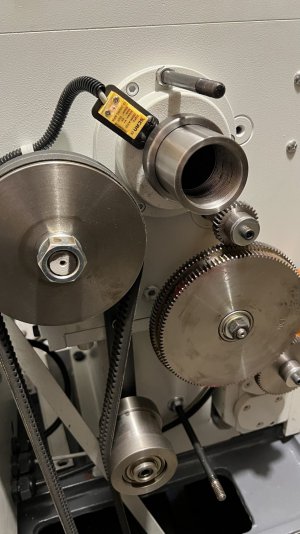

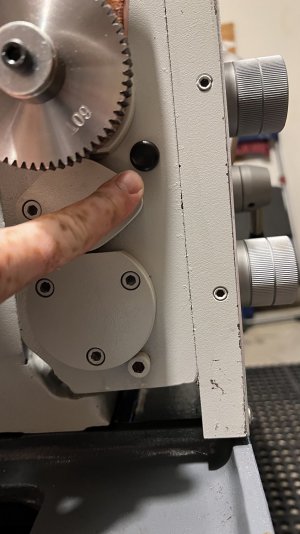

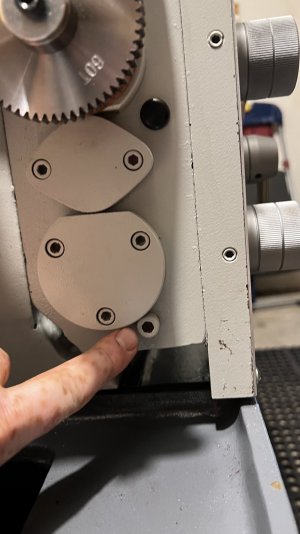

Pics for reference

Pics for reference