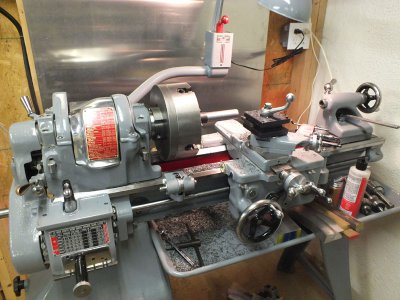

Congratulations!!! Fine job you have done. That is an early model SB,with the lever on top of the QC box. It probably won't run fast enough to properly use carbide.

How accurate a straight bar will it cut,measured at each end and in the center for parallelism? I know you have said the ways were in good condition. If there is wear on the front way,there will be a little vertical "cliff" where the apron has "sunk"(worn) into the bed. Strange someone put Turcite on the apron if nothing was worn. Maybe they just did it to make the apron slide smoother? Not that they wouldn't slide smoothly in the first place. I think you're lucky someone did do that. It would save wear on the ways for sure.

If there's no scraping at all on the ways,I'm wondering if someone had the bed re ground at some point. On a lathe that early,there would be a scraped bed on it. If it was re ground,you are again very lucky. On old lathes,not only wear can happen,but I have seen beds warp. I rebuilt a Rockwell lathe not all that old. Probably from the 60's. Its bed had warped about .010" upwards near the tail end. I had to re cut the bed due to that and other wear. The bed was hardened,too.

I'm also wondering if the large dials on your machine were added later. I don't know offhand when large dials came out. They are a definite improvement over the very small ones found on earlier lathes.

)

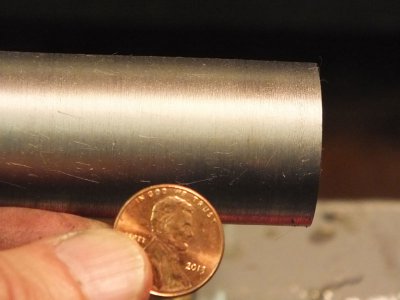

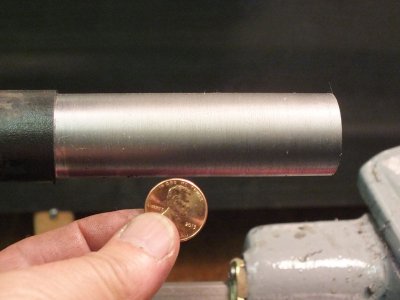

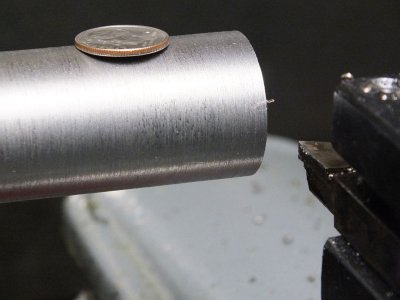

I had to slow it down for hss to get a decent cut and not overheat the cutter. My set up right now is on the slower of the 2 underdrive pulleys, that gives me some good adjustment with the spindle pulleys. On the fast underdrive pully it really hums, although I don't really know what rpm. What I think really happened with this lathe, and it's just a guess, is that at some point someone did a half a** restore on it. they added the turcite for some reason, it seems to be a common practice with machine rebuilders around here and of the time. Then they did the poor job on the spindle bearings which pretty much ruined the lathe and probably made it useless. Then it sat unused for the rest of it's life in a building in Detroit forgotten about till I found it and saved it. That is why I believe the parts and gears where in such good condition and the apron was not packed with chips. Will it be perfect as far as bed wear? I don't know, I'll have to finish with the set up and testing and I will post my findings good or bad. I will say this, everything works as it should and it is fun to use so far, I am still learning it though.

I had to slow it down for hss to get a decent cut and not overheat the cutter. My set up right now is on the slower of the 2 underdrive pulleys, that gives me some good adjustment with the spindle pulleys. On the fast underdrive pully it really hums, although I don't really know what rpm. What I think really happened with this lathe, and it's just a guess, is that at some point someone did a half a** restore on it. they added the turcite for some reason, it seems to be a common practice with machine rebuilders around here and of the time. Then they did the poor job on the spindle bearings which pretty much ruined the lathe and probably made it useless. Then it sat unused for the rest of it's life in a building in Detroit forgotten about till I found it and saved it. That is why I believe the parts and gears where in such good condition and the apron was not packed with chips. Will it be perfect as far as bed wear? I don't know, I'll have to finish with the set up and testing and I will post my findings good or bad. I will say this, everything works as it should and it is fun to use so far, I am still learning it though.