- Joined

- Dec 6, 2015

- Messages

- 809

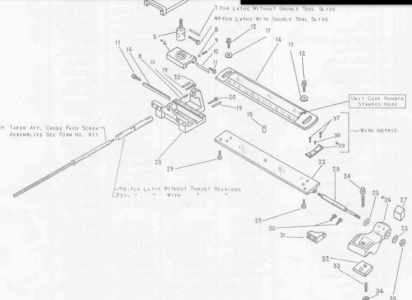

Can someone with a Heavy 10 grab some dimensions of the swivel bar (or have a build sheet specifying the dimensions) ? I'd like to know if I'm moving in the right direction in restoring everything this thing came with.