- Joined

- Dec 31, 2020

- Messages

- 75

D1-5 is a must. Would like to maintain 2" bore, besides PMs 8" is not available (and it's under 2").

Planned for rifle barrel and action work.

Things I wonder about.

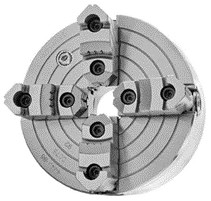

Two piece jaws or solid?

Any reason to consider 10" over 8"?

Semi-steel?

Would go over $1000, or not! WTH, it's only money.

Store brand $400? Gator $600?

Bison $900? Not Chinese, a definite preference.

Planned for rifle barrel and action work.

Things I wonder about.

Two piece jaws or solid?

Any reason to consider 10" over 8"?

Semi-steel?

Would go over $1000, or not! WTH, it's only money.

Store brand $400? Gator $600?

Bison $900? Not Chinese, a definite preference.