- Joined

- Sep 20, 2019

- Messages

- 1,331

Hi everyone,

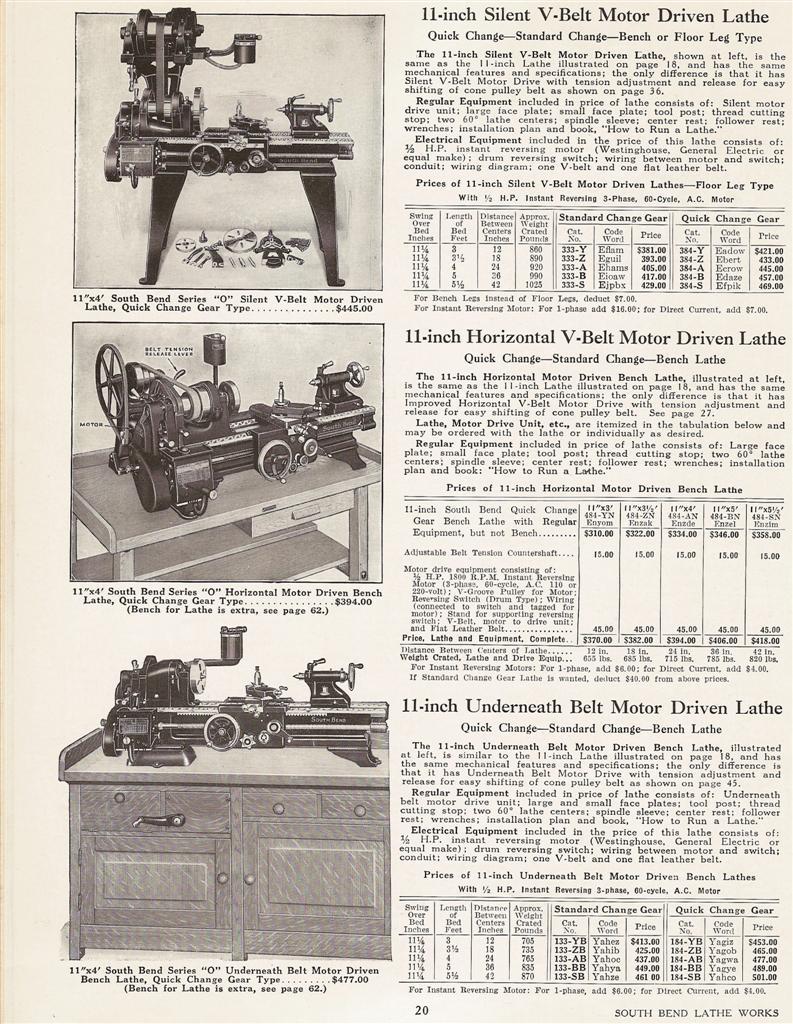

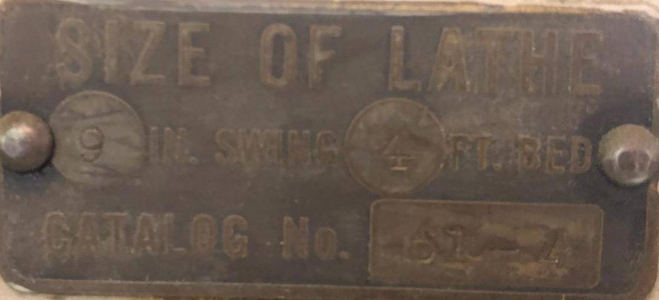

This is my first post. I'm a home hobbyist and not quite a year ago bought my first machinery - a Shoptask 1720. I'm still a rookie but want to move up as my budget will allow. I'm looking at a SB 9" x 48" for sale in my area. It's advertised having catalog # 61-A. I searched online for information about it, but can't find anything that matches this one's looks, particularly the overhead motor. I want threading capabilities and something I won't grow out of too quickly. If any of you recognize it and can tell me more about it before I look at it this weekend, I'd appreciate it. For example, does it have gears or is there anything I should ask or specifically look at and test before making a decision?

Thanks

This is my first post. I'm a home hobbyist and not quite a year ago bought my first machinery - a Shoptask 1720. I'm still a rookie but want to move up as my budget will allow. I'm looking at a SB 9" x 48" for sale in my area. It's advertised having catalog # 61-A. I searched online for information about it, but can't find anything that matches this one's looks, particularly the overhead motor. I want threading capabilities and something I won't grow out of too quickly. If any of you recognize it and can tell me more about it before I look at it this weekend, I'd appreciate it. For example, does it have gears or is there anything I should ask or specifically look at and test before making a decision?

Thanks