I meant to look at your reply to this. Sorry. Another note. If the chain was not replaced before it hit the maximum 1/16" over 12" pin to pin wear, and a ruler will work fine, then is is possible, and likely, the worn chain will be mated to worn cogs on the gear cluster and chain rings. So it's quite possible that while the derailleur is fine, the shifting problem is that the chain can't cleanly release from one cog to another. To add a little more about chain wear.

What is being measured is the wear that can't be seen to the hole in the inner link the pin passes through as mentioned. The acceptable elongation is not to exceed 12-1/16" pin to pin and if you are even close the cogs and chain ring have started to be effected. Sadly what needed to be measured is the old chain. "But" that's not all.

The rollers roll on swedging, not the pin and the swedging will also wear. That can only be checked with a chain wear tool that will push two rollers apart to see what that gap is checking the wear on the swedging. Some really old school mechanics won't believe the gauge "Because the ruler shows the chain to be just fine." They don't understand there are two wear points.

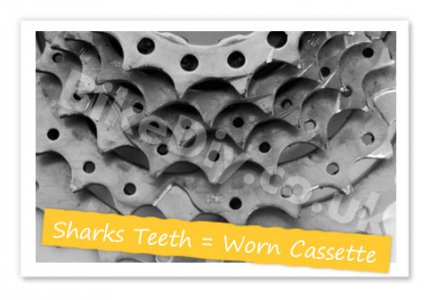

Unless the cogs and chain ring are really worn, this can be hard to detect by eye and there isn't a gauge that can be used. The best eyeball check is to see if the cogs, use the range in the center where people generally ride the most, have developed what's often called a "shark fin."

Put a piece of paper behind the cogs and see how they compare to 1st & 10th usually least used cogs. One other test is to use a length of newish chain, hang it over the rear of the cogs, then lift up on the lower end and as it "un-peals" from the cogs see if it tends to catch and start to rotate the cogs rather than detach. Here is a "borrowed" picture of a really bad one. The image is cached somewhere on the 'net: The broken

link is to a bike DIY site so I hope they won't be too bothered.

View attachment 475278

I'm going to back way up for a minute and share my general bike pre-ride assessment and troubleshooting guide.

A- Air. No air we can't ride. Quick advise. If you don't know how to clock your tire, look it up. Makes finding a leak and as importantly if what caused it is still in the tire, much easire.

B - Brakes. Bad brakes will equal a bad day.

C - Chain and Cables. No chain is just a coster bike. The brake pads may be good and properly adjusted, but if the cables aren't working properly, see "B" above.

D - Derailleur. No derailleur, and we have a hard to pedal single speed.

And of course the shifters that operate the derailleur. Our check earlier of the cables may have given us something to start checking.

Quick note if you don't know. The housing for the shifters is differant than the brake housing. The shifter housing has wire that runs parallel to the cable. Indexing shifters can't tollerate, the tollerance is too loose, cable housing compression. The cable must start to move as soon as the shifter moves. Brake cable housing are coiled as the brake leavers will overcome the compression of the housing. Highly unlikly due to the type shifter you have they got mixed up. The quick way to tell is the completly release the rear derailleur cable and slide off the last housing section and look at th end. You should see a bunch of wire ends, not the, hopfully when it's a brake cable, beveled end of a coil.

Ron