- Joined

- May 3, 2017

- Messages

- 1,997

And I suppose the tools you make are capable of maintaining the tools for fixing your tools that you use to make tools for making tools.I have tools for fixing my tools so I can make tools for making tools....

And I suppose the tools you make are capable of maintaining the tools for fixing your tools that you use to make tools for making tools.I have tools for fixing my tools so I can make tools for making tools....

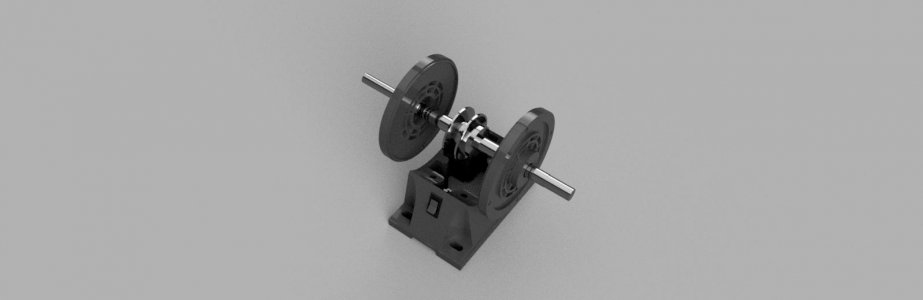

Cool Idea MatthewSX, use it as a pillow block, and just cut a slot in the frame to run the belt through.

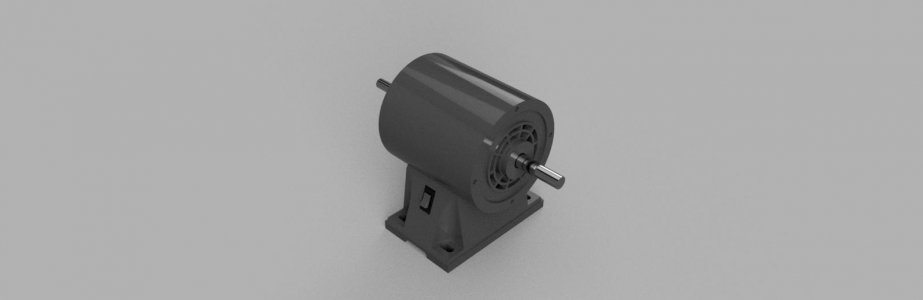

Or, gut the motor and figure out a way to attach a pulley to the shaft.

Then drive it with a variable speed motor mounted behind the tool.

John

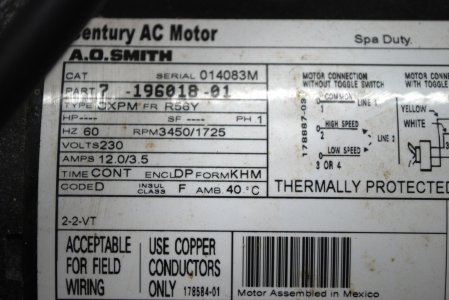

Will:Sorry Bill, I can't help with your motor issue. Were you sanding something when it failed or did it just happen one day when you turned it on? I'm just curious since I have the Jet variant.

I've only had mine for a a couple of yrs or so but I really hope mine doesn't fail like that. Hopefully you can get it fixed. BTW I put a glass platen on mine too, such a really big improvement over the crappy stock platen.