- Joined

- Dec 5, 2013

- Messages

- 5

All,

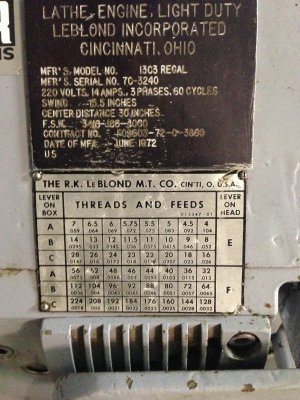

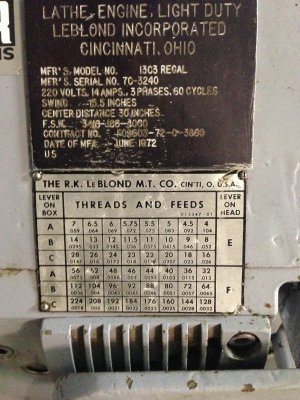

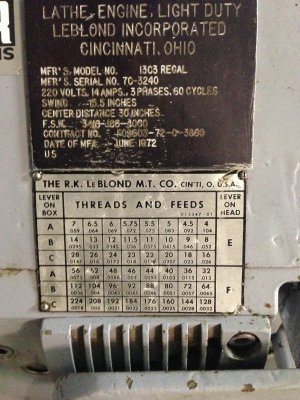

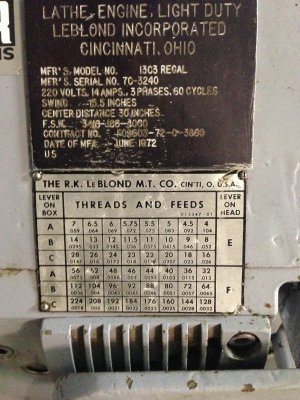

To start it off I am a bit overwhelmed with all of the various models and wiring application types of VFD's. Below are the images I felt would be needed to provide sufficient feedback. Beneath the photos are additional details.

I am working within a shop approximately 100ft away from my household 200 amp breaker box. The shop is only wired for 110 currently. My hopes were to convert the 1HP 3 phase mill via a 110volt VFD on the current breaker. For the lathe I anticipate running 220 volt with a VFD to power the 3 phase 3HP. I have seen several recommendations for a Teco model...I would say $200 on the 1HP and $250 on the 3HP is the upper band I would like to be at from a cost perspective-It appears this is reasonable from what I am reading and for the limited work these machines will see. However, if the quality at this price-point is believed to be undesirable I'm open for opinions.

Here are my questions:

What VFD is recommended for the 1 HP 3 Phase Mill?

What VFD is recommended for the 3 HP 3 Phase Mill?

Can I run a 30 amp breaker 220 for the lathe-will also be used for small wire welder, etc..?

If so, what is the recommended wire size?

Not crucial but I would like to maintain current power switches on the machines, is this reasonable?

What am I missing?

The control box for the lathe does not appear to have loaded correctly, if that is the case I can email to whomever is willing to assist. By all means my electrical know how is lacking...please forgive any ignorant questions.

I am restoring/servicing the machines now so I have a week or so before placing an order. Thanks ahead of time for the assistance

-Chris

To start it off I am a bit overwhelmed with all of the various models and wiring application types of VFD's. Below are the images I felt would be needed to provide sufficient feedback. Beneath the photos are additional details.

I am working within a shop approximately 100ft away from my household 200 amp breaker box. The shop is only wired for 110 currently. My hopes were to convert the 1HP 3 phase mill via a 110volt VFD on the current breaker. For the lathe I anticipate running 220 volt with a VFD to power the 3 phase 3HP. I have seen several recommendations for a Teco model...I would say $200 on the 1HP and $250 on the 3HP is the upper band I would like to be at from a cost perspective-It appears this is reasonable from what I am reading and for the limited work these machines will see. However, if the quality at this price-point is believed to be undesirable I'm open for opinions.

Here are my questions:

What VFD is recommended for the 1 HP 3 Phase Mill?

What VFD is recommended for the 3 HP 3 Phase Mill?

Can I run a 30 amp breaker 220 for the lathe-will also be used for small wire welder, etc..?

If so, what is the recommended wire size?

Not crucial but I would like to maintain current power switches on the machines, is this reasonable?

What am I missing?

The control box for the lathe does not appear to have loaded correctly, if that is the case I can email to whomever is willing to assist. By all means my electrical know how is lacking...please forgive any ignorant questions.

I am restoring/servicing the machines now so I have a week or so before placing an order. Thanks ahead of time for the assistance

-Chris