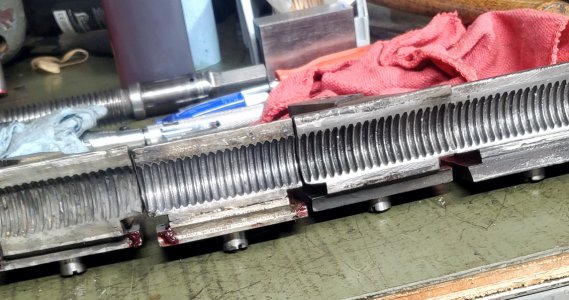

I was preparing to put the carriage back on the lathe and decided to reinspect all of the oil passages to be sure they were all clean. I discovered that I had missed a couple. There are two passages that provide oil to the cross slide dove tails.

The one on the left I had cleared yesterday... the one on the right I missed clearing it.

I couldn't figure out how it tied into the oiling system... I knew it did, but how? There would have to be a horizontal hole drilled somewhere to connect it to the system... and that hole would have to be drilled from the outside, but I couldn't see where.

I had put compressed air on it a couple of times trying to determine where it came out... but it acted like a blind hole... no air escaping anywhere.

I finally turned the air pressure up some and tried it again... this time something popped and blew a wad of gunk and degreasing fluid out the left hand hole... right into my face.

I'm glad I was wearing safety glasses... and had my mouth closed...

So now I knew which direction the connecting hole went... I started scraping thick paint off the side of the carriage and found the plug...

I removed the plug and cleaned that hole out.

The other one that I missed was a passage that provided oil to the rear way...

I hadn't noticed it because I didn't realize the oiling system oiled the rear way.

Again, I could not figure out how this hole was connected to the system... I scraped all the paint off on every surface that was square to the hole... no plugs anywhere. I was putting air to all possible passages, trying to get some air out of that hole... no luck. After an hour of fooling with it, I still had no idea.

Then I suddenly realized how Hendey did it...

There is a groove machined in the left side of the carriage... it is filled with what appears to be an asphalt based filler...

I had been wondering what that groove was for... there is a brass tube inserted into that groove, then the filler covers the tube. You can see part of the tube where the filler has worn away. This tube has two bends at each end... the front 'dogleg' connects to the oiling system and the back 'dogleg' connects to the hole over the rear way.

It is completely clogged... and there is no way to clean it out. It would have to be removed and replaced, then the groove refilled. I'll just manually oil the rear way...

Anyway, I've now reassembled the carriage, cut and installed new felt way wipers, and reinstalled the carriage and apron...

I filled the apron with Vactra 2 and ran the carriage down the bed back and forth until it started pumping oil out the holes...

The oiling system is working great... I'm glad, I didn't want to have to take it apart again...

-Bear