- Joined

- Mar 25, 2013

- Messages

- 4,614

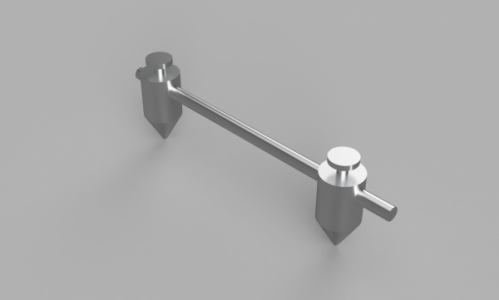

I started this idea in Fusion, now making some parts.

Thumbscrews first:

This brings up an interesting debate on order of operations. When making thumbscrews it is suboptimal to grip the work by the knurl or by the thread. How do you go about this? I cut the knurl after making the shape but before threading. Then I cut the thread and parted off. Then I had to grip on the threads to chamfer the ends of the knurled part. Worked OK, but is there a better order? What if you started with knurled bar? Knurling is always a gamble for me so I hate to do it last.

Robert

Thumbscrews first:

This brings up an interesting debate on order of operations. When making thumbscrews it is suboptimal to grip the work by the knurl or by the thread. How do you go about this? I cut the knurl after making the shape but before threading. Then I cut the thread and parted off. Then I had to grip on the threads to chamfer the ends of the knurled part. Worked OK, but is there a better order? What if you started with knurled bar? Knurling is always a gamble for me so I hate to do it last.

Robert