I have made a set of two grey cast iron lapping plates and rubbing them on dyed granite reference surface indicates that they are sufficiently flat. I expect that they will need be re-conditioned to restore the flatness after some use and my question is whether it is really necessary to use the third plate in the process. For what it's worth I use garnet abrasives only.

From what I have read on the subject, rubbing two plates against each other will result in the top plate becoming concave and the bottom plate convex so the third plate is needed to correct that. My question is can the correction be done by simply swapping the positions of the two plates so that the top one becomes bottom and vice versa ?

From what I have read on the subject, rubbing two plates against each other will result in the top plate becoming concave and the bottom plate convex so the third plate is needed to correct that. My question is can the correction be done by simply swapping the positions of the two plates so that the top one becomes bottom and vice versa ?

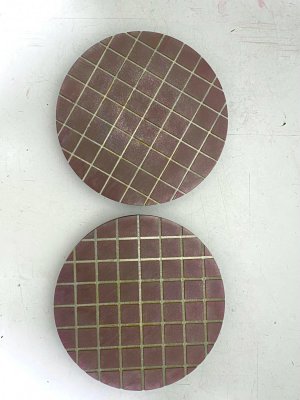

Attachments

Last edited: