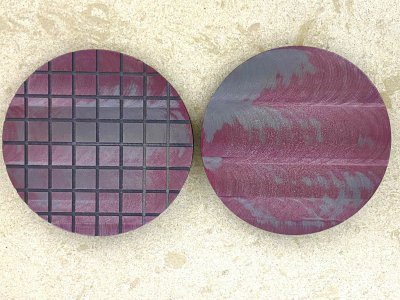

Yes. I didn't know anything about embedding until I learned it the hard way. When I first tried lapping I used diamond to lap a steel plate and after finishing it and cleaning it all over, I put the plate on the table of my mill and slided it across. The result is shown in the photo belowAnother significant point is that after the two plates are charged with abrasive, they could not be used in contact with the surface plate without causing wear and inaccuracy to it.

Attachments

Last edited: