- Joined

- May 27, 2016

- Messages

- 3,469

The motivation is to find some cheap and cheerful reasonable substitute for Dykem and similar that just cannot be had in less well served places.

I do like Dykem, but a whiff of the organic solvents makes my chest wheeze up somewhat more readily than alcohols.

The varnish layer left from dried Dykem is some kind of cellulose. I chose to try out the "traditional" natural shellac varnish, as might be used in French polish.

The rest of what is in there can be any alcohol solvent. I avoid the shatteringly expensive "rectified alcohol", which is booze - if you dilute it.

Even gasoline petrol works, if you can stand the smell. I went for IPA. IsoPropyl Alcohol, the main ingredient of rubbing alcohol, or de-natured alcohol, or methylated spirits. IPA is clean, and does not smell awful. The colors dye was by raiding a red ball-point pen that I know I did not buy.

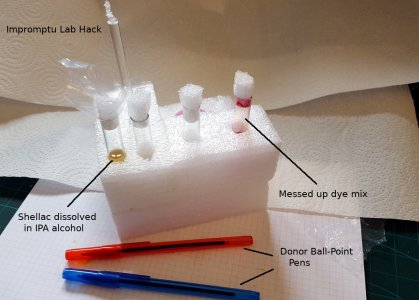

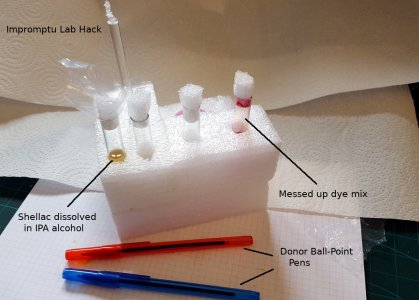

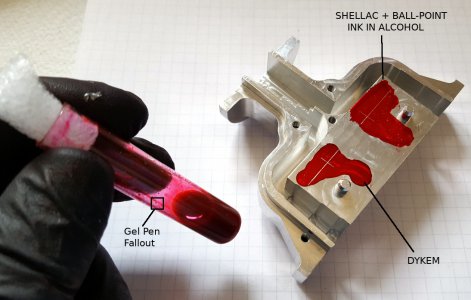

It got to look a bit "chemistry lab" around me. Be warned to use gloves, and take care not to let even the least smear of dye get loose. Even the attempt to clean it up then spreads to all you touch afterwards, and all your paper stuff starts going pink. The most fraught moment is when you get a grip on the metal ball-point tip with the little pliers. Try and ease it out with rotations, no sudden moves or jerks from direct pulls.

_

_

First thing is, the shellac flakes do not dissolve in seconds. They settle into the bottom of the container, and need to be stirred up of shook regularly.

My 100g of blonde flakes cost about £6.50 . Left to itself, they might dissolve in about 8 hours, but you can massively speed things up if you crush them up. They splatter all over the place. One individual uses a small coffee grinder. Maybe a mortar & pestle would be good, but I settled for 2 batches of 500mg each, crushed up a bit between two spoons. Things went a whole lot better when I pounded them with the end of a 10mm drill bit while they were confined to a detergent bottle cap.

Warm it up a bit, and work it, and you can get it down to about half an hour. It's much easier to just leave it to itself for a while.

I had a little try with using aftermarket inkjet refill ink. The colours one can get are beautiful, but too thin and not concentrated enough. They are water-based, which does mix with the alcohol, but extends the drying time. Possibly if one drove off some of the water by cooking it a bit, the dye would concentrate, just like salt in chilli sauce.

_

_

Drying Time

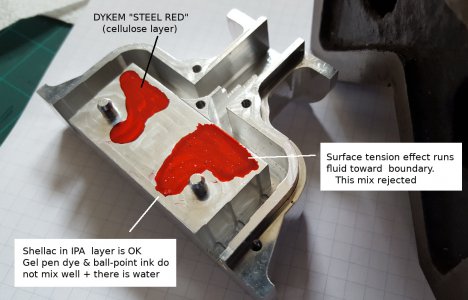

Dykem "Steel Red" takes 4 minutes & 20 seconds to just about dry. The shellac 500mg in about 6mL of IPA took very nearly the same. Within some few seconds.

Comparing..

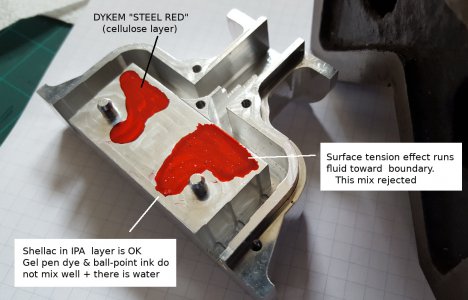

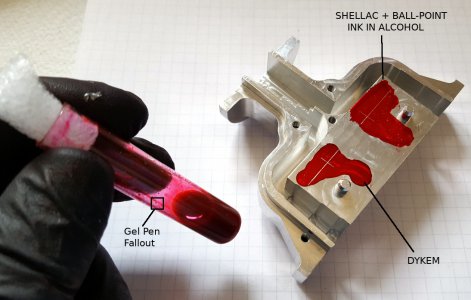

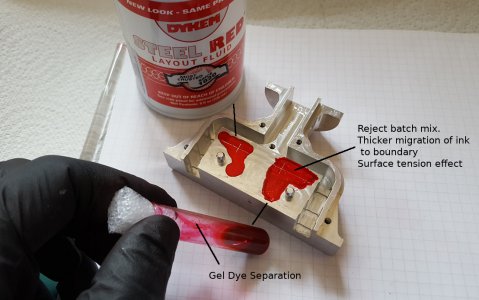

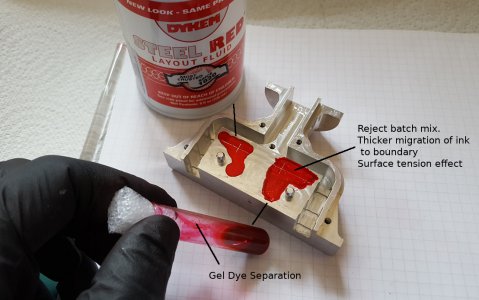

What I show here is not the final mix. I was still making a mess. I learned not to mix gel-pen dye with traditional ball-point ink. It caused little tiny lumps to separate, and the fluid in it messed up the spreading effect so that as it dried, it seemed to have a "thicker" accumulation at the ink layer edge. The tiniest touch of a little detergent completely changes things, but it was how I decided I was seeing a surface tension effect. If one stays with the pure IPA and shellac, then it becomes hard to tell the difference between Dykem and the homebrew concoction. I first tried it on the flea-market V-block that is now promised some respite from rusting away.

This is where I compared the drying times. The durability to handling, and the way it wipes off with alcohol seem the same.

_

_

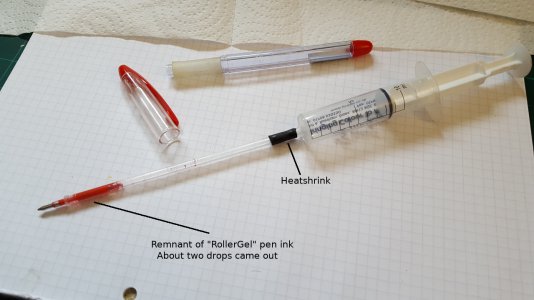

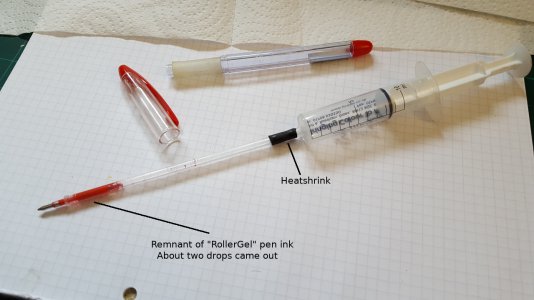

I also tried it out on clean aluminium, and added some scribe lines. The amount of ink in a ball-point pen is surprisingly little. A 110mm plastic tube has inner diameter 1.5mm, and that would be 0.185mL, then take off some because the tube always has an empty bit at the end. It will have a few drops - maybe 4 or 5.

One tip is not to blow the ink out with air. Things go much better if you push it out with alcohol So one drop of ball-point pen ink stains up the fluid you see in the pictures, which by the time they were spread, had used about 15mL to 20mL of alcohol. I am sure one could use other dyes.

_

_

The pictures are by no means the final try. They are of the work-in-progress failed messed up tries, but already, we obviously have a viable low cost and reasonable alternative. If one can get hold of some shellac, then as I said to @Suzuki4evr, the rest of it could be one abandoned ball-point and if lacking some IPA, then maybe a little gasoline stolen from the girlfriend's motor cycle. Hardware store methylated spirits or de-natured alcohol will do.

There can, of course, be refinements, but already, it's kinda working!

I do like Dykem, but a whiff of the organic solvents makes my chest wheeze up somewhat more readily than alcohols.

The varnish layer left from dried Dykem is some kind of cellulose. I chose to try out the "traditional" natural shellac varnish, as might be used in French polish.

The rest of what is in there can be any alcohol solvent. I avoid the shatteringly expensive "rectified alcohol", which is booze - if you dilute it.

Even gasoline petrol works, if you can stand the smell. I went for IPA. IsoPropyl Alcohol, the main ingredient of rubbing alcohol, or de-natured alcohol, or methylated spirits. IPA is clean, and does not smell awful. The colors dye was by raiding a red ball-point pen that I know I did not buy.

It got to look a bit "chemistry lab" around me. Be warned to use gloves, and take care not to let even the least smear of dye get loose. Even the attempt to clean it up then spreads to all you touch afterwards, and all your paper stuff starts going pink. The most fraught moment is when you get a grip on the metal ball-point tip with the little pliers. Try and ease it out with rotations, no sudden moves or jerks from direct pulls.

_

_

First thing is, the shellac flakes do not dissolve in seconds. They settle into the bottom of the container, and need to be stirred up of shook regularly.

My 100g of blonde flakes cost about £6.50 . Left to itself, they might dissolve in about 8 hours, but you can massively speed things up if you crush them up. They splatter all over the place. One individual uses a small coffee grinder. Maybe a mortar & pestle would be good, but I settled for 2 batches of 500mg each, crushed up a bit between two spoons. Things went a whole lot better when I pounded them with the end of a 10mm drill bit while they were confined to a detergent bottle cap.

Warm it up a bit, and work it, and you can get it down to about half an hour. It's much easier to just leave it to itself for a while.

I had a little try with using aftermarket inkjet refill ink. The colours one can get are beautiful, but too thin and not concentrated enough. They are water-based, which does mix with the alcohol, but extends the drying time. Possibly if one drove off some of the water by cooking it a bit, the dye would concentrate, just like salt in chilli sauce.

_

_

Drying Time

Dykem "Steel Red" takes 4 minutes & 20 seconds to just about dry. The shellac 500mg in about 6mL of IPA took very nearly the same. Within some few seconds.

Comparing..

What I show here is not the final mix. I was still making a mess. I learned not to mix gel-pen dye with traditional ball-point ink. It caused little tiny lumps to separate, and the fluid in it messed up the spreading effect so that as it dried, it seemed to have a "thicker" accumulation at the ink layer edge. The tiniest touch of a little detergent completely changes things, but it was how I decided I was seeing a surface tension effect. If one stays with the pure IPA and shellac, then it becomes hard to tell the difference between Dykem and the homebrew concoction. I first tried it on the flea-market V-block that is now promised some respite from rusting away.

This is where I compared the drying times. The durability to handling, and the way it wipes off with alcohol seem the same.

_

_

I also tried it out on clean aluminium, and added some scribe lines. The amount of ink in a ball-point pen is surprisingly little. A 110mm plastic tube has inner diameter 1.5mm, and that would be 0.185mL, then take off some because the tube always has an empty bit at the end. It will have a few drops - maybe 4 or 5.

One tip is not to blow the ink out with air. Things go much better if you push it out with alcohol So one drop of ball-point pen ink stains up the fluid you see in the pictures, which by the time they were spread, had used about 15mL to 20mL of alcohol. I am sure one could use other dyes.

_

_

The pictures are by no means the final try. They are of the work-in-progress failed messed up tries, but already, we obviously have a viable low cost and reasonable alternative. If one can get hold of some shellac, then as I said to @Suzuki4evr, the rest of it could be one abandoned ball-point and if lacking some IPA, then maybe a little gasoline stolen from the girlfriend's motor cycle. Hardware store methylated spirits or de-natured alcohol will do.

There can, of course, be refinements, but already, it's kinda working!

Last edited: