- Joined

- Jun 1, 2018

- Messages

- 154

I am doff when it comes to maths. I was reading a practical machinest thread about tapers. The guy did the maths but made some elementry error. I just could not understand it. I dont know what minutes ,seconds and radians are,

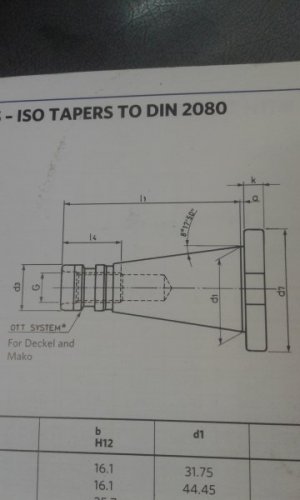

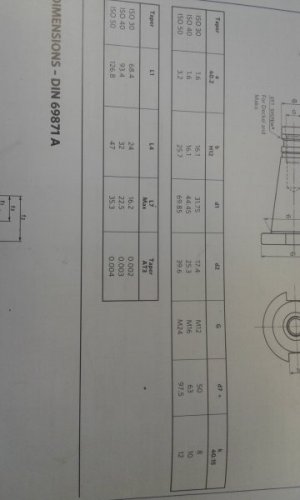

So I would like to know if there is a correct way to do this.I once had a well made homemade sine bar ,case hardened and ground but it was stolen. So ,without bluffing myself ,how would one set up the compound to cut an iso 40 taper when you are clueless in math.Also it seems that some good thought process is needed here as one runs out of options on how to hold your workpiece and keep deadnuts contricity.

What would be the logical steps for making an iso 40 arbor for a thirteen mm chuck.

Are you happy with the accuracy and feel of that keyless chuck and where and how much did it cost?Looks like your lathe gives a real good finish .What inserts do you use.?

So I would like to know if there is a correct way to do this.I once had a well made homemade sine bar ,case hardened and ground but it was stolen. So ,without bluffing myself ,how would one set up the compound to cut an iso 40 taper when you are clueless in math.Also it seems that some good thought process is needed here as one runs out of options on how to hold your workpiece and keep deadnuts contricity.

What would be the logical steps for making an iso 40 arbor for a thirteen mm chuck.

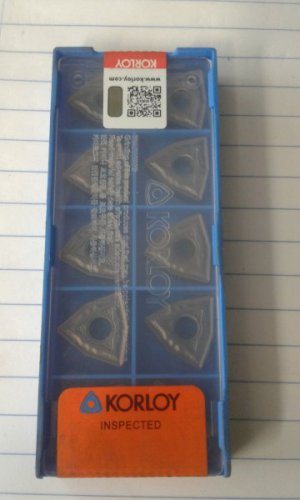

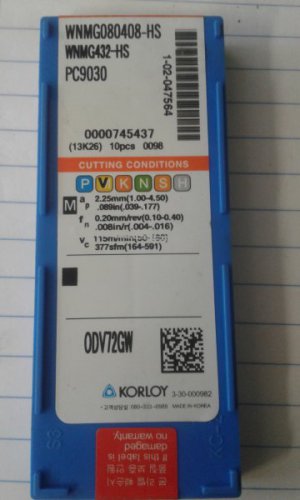

Are you happy with the accuracy and feel of that keyless chuck and where and how much did it cost?Looks like your lathe gives a real good finish .What inserts do you use.?