- Joined

- Mar 8, 2015

- Messages

- 309

Looking good!

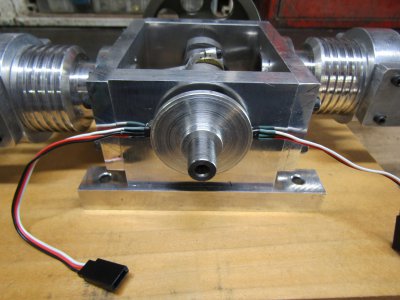

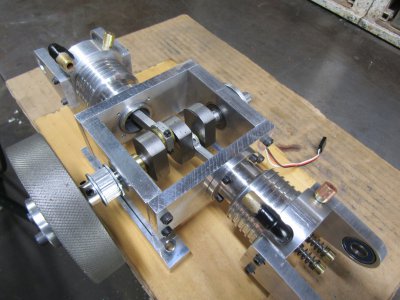

Since the cams are individually adjustable it is easier for me to just pull the cam shaft out the side. If I remove the cam mounts then I would have to reset the valve clearance and alignment of the shaft. Not hard to do but finicky to get everything set back in place.Perhaps easier to not loose cam indexing, just unbolt the mounts from the head with the shaft in place.

Thanks Gray that does sound nice and will set it offdeep red ion the inside part

Still open to suggestions but will probably leave it like it is for now.Just my opinion, but I like raw metal!