-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to get this spindle nut off my DoAll

- Thread starter Brento

- Start date

- Joined

- Dec 18, 2019

- Messages

- 6,447

Try hitting/tapping the wrench with a dead blow hammer for impact. Might break it loose with a small impact. Otherwise you need to keep the spindle from rotating while unscrewing. Bet it won't take much to break it free.

- Joined

- Jan 31, 2016

- Messages

- 11,454

Put the wrench on and hit it with a hammer . Yes , left hand threads . The hub should shock loose even if not locking the spindle .

Oh yeah . I think you need a surface plate and height gage to go along with that new grinder .

Oh yeah . I think you need a surface plate and height gage to go along with that new grinder .

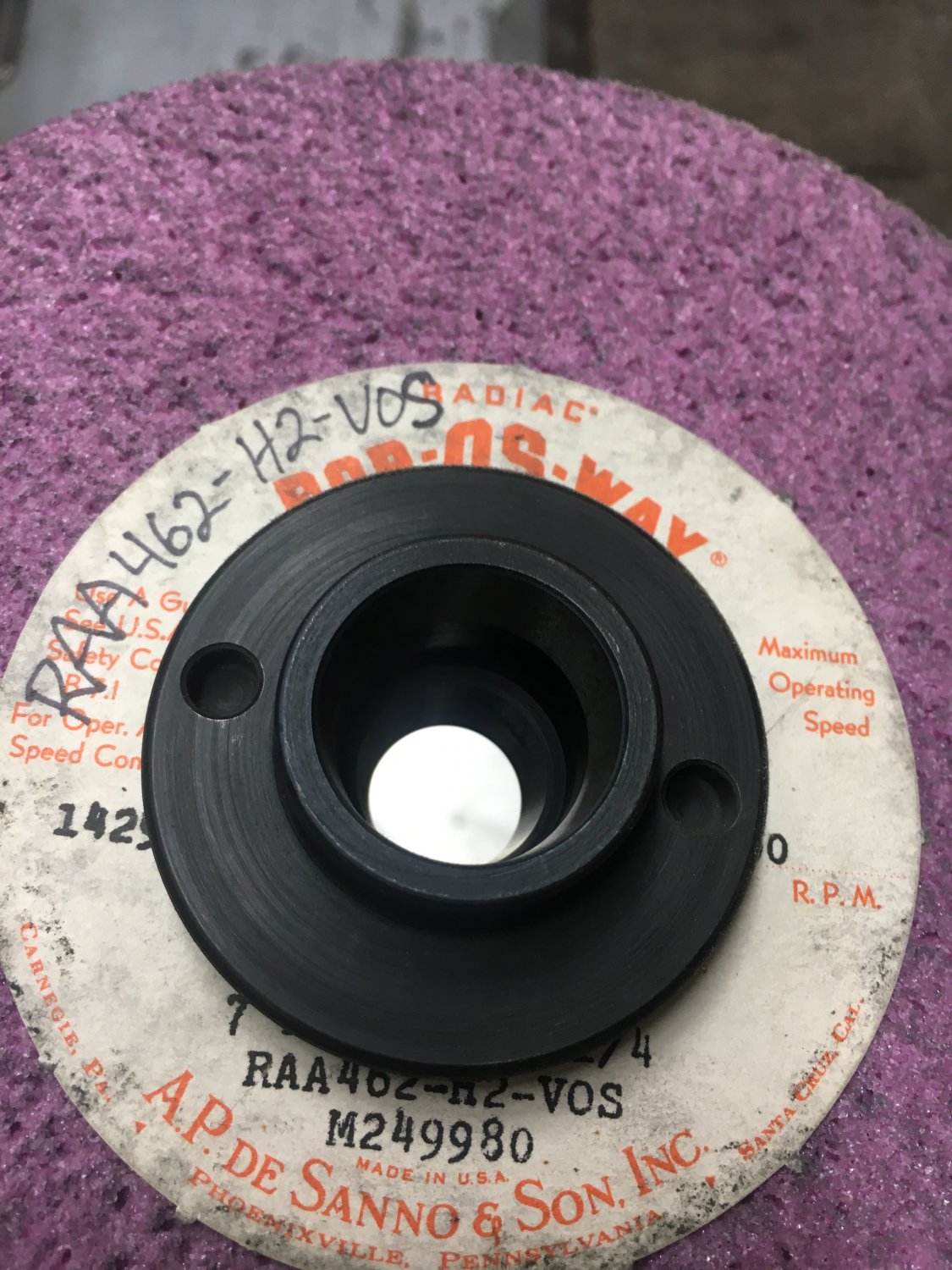

To be alittle more clear about this. A standard sopko hub has spanner holes on the backside of the hub and another set on the hub nut. Then their is the spindle nut that retains the hub to the spindle and has the slot cut into it.

Spindle side (backside)

Nut side (front side)

Nut side (front side)

To remove the hub from the spindle I take the pin spanner wrench and engage the holes on the backside of the hub. I have the head low enough so once the wrench is engage with the holes I spin the wrench to touch the magnet side or the wheel guard To keep from spinning. Then I use another wrench with the slot end and spin the spindle nut off. It can be challenging if really tight. That spindle nut shouldnt be torqued tight. Hammering on a spindle is a NoNo. Taps I guess but you really shouldn’t have the stuff that tight. I personally don’t do any mounting or dismounting of wheels on the spindle I use a mounting tool on a bench then balance the wheel.

To take the hub nut off you typically do it with two pin spanner wrenches. One in the front holes you can see, and one wrench in the rear hub holes.

To help the process I’ve made acouple tools to help the process. One mounts in the vise to hold the hub while mounting and dismounting of wheels. I usually mount a wheel and leave it for the life of the wheel. The second tool is a spindle nut socket tool. Made from a wrist pin of a piston. I ground in the tang to a tight fit. The hex end allows me to use a wrench to loosen at any degree. So it’s not at a awkward angle.

Spindle side (backside)

To remove the hub from the spindle I take the pin spanner wrench and engage the holes on the backside of the hub. I have the head low enough so once the wrench is engage with the holes I spin the wrench to touch the magnet side or the wheel guard To keep from spinning. Then I use another wrench with the slot end and spin the spindle nut off. It can be challenging if really tight. That spindle nut shouldnt be torqued tight. Hammering on a spindle is a NoNo. Taps I guess but you really shouldn’t have the stuff that tight. I personally don’t do any mounting or dismounting of wheels on the spindle I use a mounting tool on a bench then balance the wheel.

To take the hub nut off you typically do it with two pin spanner wrenches. One in the front holes you can see, and one wrench in the rear hub holes.

To help the process I’ve made acouple tools to help the process. One mounts in the vise to hold the hub while mounting and dismounting of wheels. I usually mount a wheel and leave it for the life of the wheel. The second tool is a spindle nut socket tool. Made from a wrist pin of a piston. I ground in the tang to a tight fit. The hex end allows me to use a wrench to loosen at any degree. So it’s not at a awkward angle.

I have both lol. Height gage is just a base and rod but ive got one.Put the wrench on and hit it with a hammer . Yes , left hand threads . The hub should shock loose even if not locking the spindle .

Oh yeah . I think you need a surface plate and height gage to go along with that new grinder .

That nut tool will be on my list to make. The spindle nut and wheel were on this grinder when i bought it. I have not taken it off yet. Just finishing my last bit of cleaning still. I will have to prob find another wrench it looks like so i can get farther then.To be alittle more clear about this. A standard sopko hub has spanner holes on the backside of the hub and another set on the hub nut. Then their is the spindle nut that retains the hub to the spindle and has the slot cut into it.

Spindle side (backside)

View attachment 411583Nut side (front side)View attachment 411584

To remove the hub from the spindle I take the pin spanner wrench and engage the holes on the backside of the hub. I have the head low enough so once the wrench is engage with the holes I spin the wrench to touch the magnet side or the wheel guard To keep from spinning. Then I use another wrench with the slot end and spin the spindle nut off. It can be challenging if really tight. That spindle nut shouldnt be torqued tight. Hammering on a spindle is a NoNo. Taps I guess but you really shouldn’t have the stuff that tight. I personally don’t do any mounting or dismounting of wheels on the spindle I use a mounting tool on a bench then balance the wheel.

To take the hub nut off you typically do it with two pin spanner wrenches. One in the front holes you can see, and one wrench in the rear hub holes.

To help the process I’ve made acouple tools to help the process. One mounts in the vise to hold the hub while mounting and dismounting of wheels. I usually mount a wheel and leave it for the life of the wheel. The second tool is a spindle nut socket tool. Made from a wrist pin of a piston. I ground in the tang to a tight fit. The hex end allows me to use a wrench to loosen at any degree. So it’s not at a awkward angle. View attachment 411582View attachment 411581

It might take three hands but if you hold the wheel with your hand then take the slot end of wrench and engage into spindle nut. With a third hand use a crescent wrench adjusted the thickness of the wrench and twist with that. Little fiddling but should work.

- Joined

- Nov 25, 2015

- Messages

- 8,310

Attachments

Last edited:

- Joined

- Jun 7, 2013

- Messages

- 10,089

Another note, if it is a Sopko adaptor, they make a wheel puller that screws into the larger ID of the adaptor and has a jack screw in the ID of the puller that bears against the spindle threads to pull the wheel adaptor off without any hammering or tapping.