- Joined

- Dec 6, 2015

- Messages

- 809

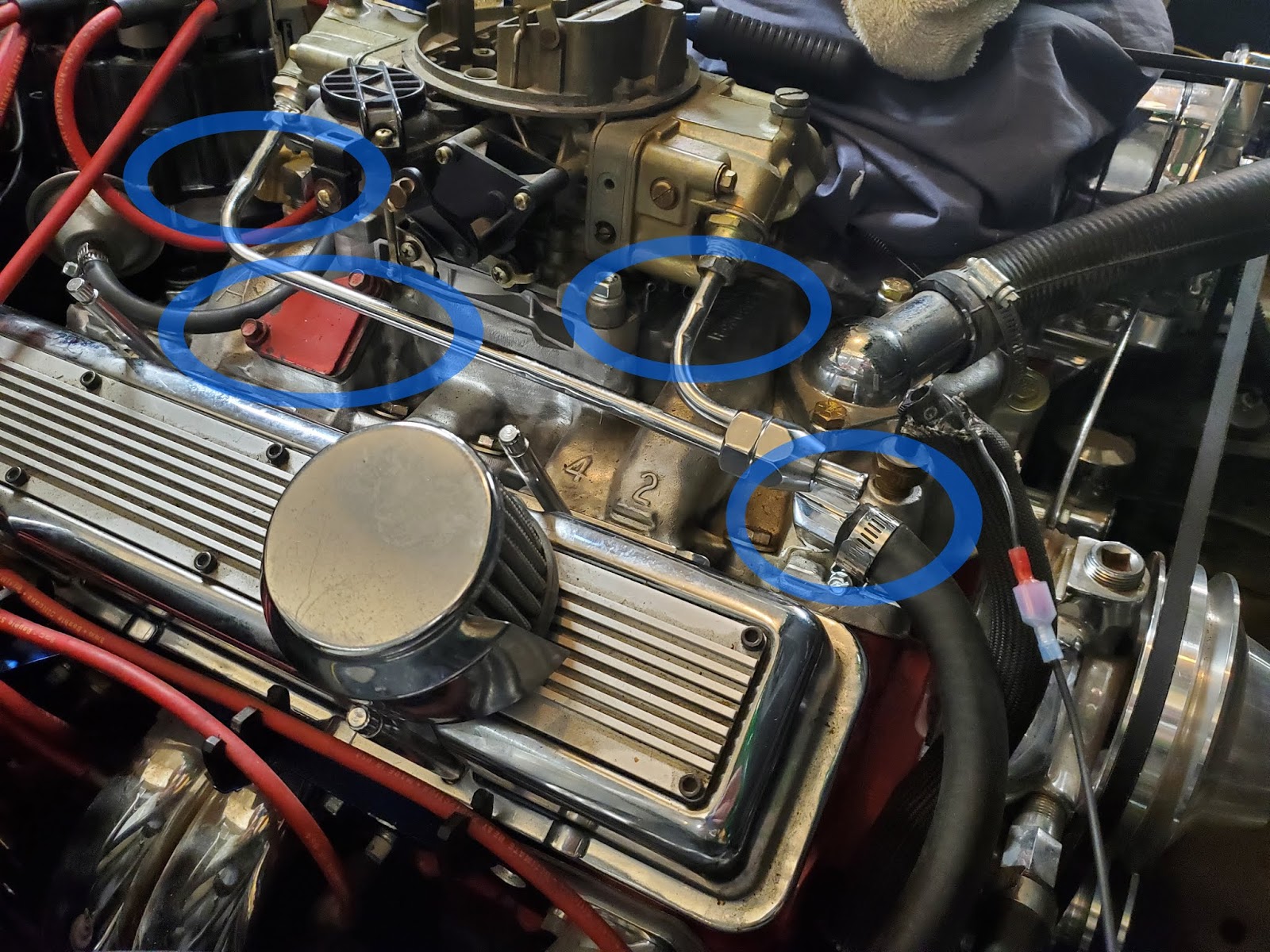

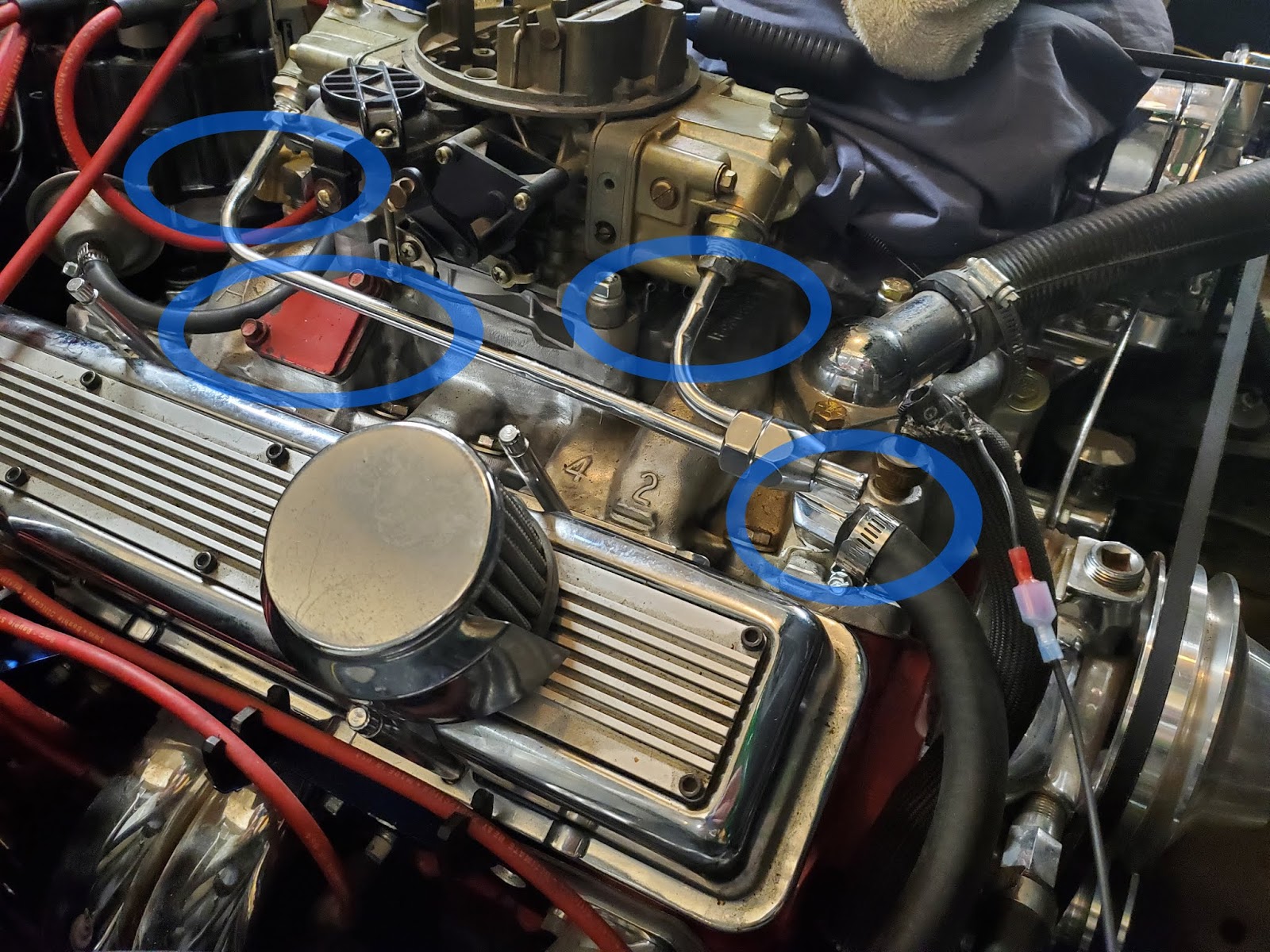

Okay. I need to re-think this. I don't want to go back to the corvette forum at all. I had a cheap dual-inlet line installed, but couldn't get it to clear. Also, it leaked. Then I bent it just to see if I could (before I had the tools to bend it). It didn't work out great at all. Here's where I sit with the carburetor sitting on it. I've got four things circled on it. Two bends in the fuel line I need to make, and two things I need to clear.

The two bends in the fuel line that I need to make coming out of the fuel inlets for the bowls are to lift the fuel line away from the block off plate and the forward fitting. These bends are about 50 degrees. The adapter for the carburetor prevented that from being a 75 degree bend. It have me just a little more clearance. The fuel pump on the front is being fed with stock 3/8" (O.D.) lines. At this point, because of the height, going with aluminum or another (softer) alloy will require me adding supports for the line. I really don't want rubber (or rubber-with-a-braid-to-look-better) because I don't want to be springing a fuel leak every few years. That leaves me with two options, plain steel or stainless steel. I have the tools now to flare and bend. I don't have the room to add adapters to go from flare fittings to the Army-Navy (AN) type fittings. I want to avoid compression fittings (I'll only do that if I am running swagelock compression fittings).

Note, this is not a race car. Because of that, I'm okay with the 3/8" fuel line set up. My intent is to run this with a smaller line to keep things less crowded. The stock line should be able to handle higher fuel pressures, allowing me to feed this engine. I will re-evaluate when I get it back on the road.

Are there tubing kits for AN-styled connections (the same form-it-yourself)? I'd have to change the carb inlet adapters from the 7/8-20-to-5/8-18 to the AN inlets. With the tight space to make that bend, I'm a lot more worried (probably a lot more than I should be). Note, those dual-inlet kits (like https://www.amazon.com/Inlet-Braide...+inlet+holley+fuel+line&qid=1578762063&sr=8-2) will be able to work around that block off plate with the spacer sitting on it, but will still be sitting directly on the intake manifold. It would put the fuel line directly on that fitting to the front. I'd rather avoid that because of heat sock and vapor lock.

What suggestions do you guys have for me?

The two bends in the fuel line that I need to make coming out of the fuel inlets for the bowls are to lift the fuel line away from the block off plate and the forward fitting. These bends are about 50 degrees. The adapter for the carburetor prevented that from being a 75 degree bend. It have me just a little more clearance. The fuel pump on the front is being fed with stock 3/8" (O.D.) lines. At this point, because of the height, going with aluminum or another (softer) alloy will require me adding supports for the line. I really don't want rubber (or rubber-with-a-braid-to-look-better) because I don't want to be springing a fuel leak every few years. That leaves me with two options, plain steel or stainless steel. I have the tools now to flare and bend. I don't have the room to add adapters to go from flare fittings to the Army-Navy (AN) type fittings. I want to avoid compression fittings (I'll only do that if I am running swagelock compression fittings).

Note, this is not a race car. Because of that, I'm okay with the 3/8" fuel line set up. My intent is to run this with a smaller line to keep things less crowded. The stock line should be able to handle higher fuel pressures, allowing me to feed this engine. I will re-evaluate when I get it back on the road.

Are there tubing kits for AN-styled connections (the same form-it-yourself)? I'd have to change the carb inlet adapters from the 7/8-20-to-5/8-18 to the AN inlets. With the tight space to make that bend, I'm a lot more worried (probably a lot more than I should be). Note, those dual-inlet kits (like https://www.amazon.com/Inlet-Braide...+inlet+holley+fuel+line&qid=1578762063&sr=8-2) will be able to work around that block off plate with the spacer sitting on it, but will still be sitting directly on the intake manifold. It would put the fuel line directly on that fitting to the front. I'd rather avoid that because of heat sock and vapor lock.

What suggestions do you guys have for me?