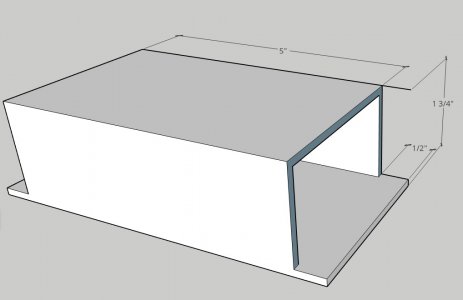

I'm new here. I am handy at making things, but never machined anything, ran a mill, ect. I have a basic part to make and have access to a Jet JMD-15. Unfortunately I don't have access to someone who knows how to use it. Attached is my part. Made from 0.125" aluminum square stock. Do I need to rough cut it on the bandsaw first? Would I use something like a flycutter to clean it up on the mill? I know its pretty basic, but could someone give me some pointers?

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to make simple part

- Thread starter tsperry88

- Start date

- Joined

- Mar 21, 2018

- Messages

- 1,597

Yes, rough cut your tubing first. A beginner should probably NEVER use a fly cutter. Use an end mill. Depending on what the end use is, you can either cut to the bottom of the cut with the end mill, or stop short and use a flat file to finish.

Also, what is a Jet JMD-15?

Also, what is a Jet JMD-15?

- Joined

- Jan 2, 2014

- Messages

- 8,852

@tsperry88,

When you said aluminum square stock, I "heard" solid.

When @SLK001 said "tube" I had to go back and re-read.

Okay, right 1/8 wall tube.....got it!

Yes, I'd pre-cut to almost finished size, and then clean it up on the mill (or with a file).

Welcome to the group!

-brino

When you said aluminum square stock, I "heard" solid.

When @SLK001 said "tube" I had to go back and re-read.

Okay, right 1/8 wall tube.....got it!

Yes, I'd pre-cut to almost finished size, and then clean it up on the mill (or with a file).

Welcome to the group!

-brino

- Joined

- Dec 27, 2014

- Messages

- 4,057

I dunno if this will get to you, seems to be a problem with the web today. Bandsaw, leaving 1/16th. Using a 1/4 to 3.8" endmill in the Jet, holding the work in a machine vise, (and the cutter in a collet, not the drill chuck) machine the rough edges to your already drawn dimensions. Take it easy, run the mill (professional courtesy Keeps me from calling it a mill/drill,)at fairly high speed, keep a light oil on the cutter, WD 40 will do, but not well. Take each cut in two passes, with the cutter to the right side of the work, moving the wrok toward you, otherwise the cutter will try to pull the work into it. (Bad News)I'm new here. I am handy at making things, but never machined anything, ran a mill, ect. I have a basic part to make and have access to a Jet JMD-15. Unfortunately I don't have access to someone who knows how to use it. Attached is my part. Made from 0.125" aluminum square stock. Do I need to rough cut it on the bandsaw first? Would I use something like a flycutter to clean it up on the mill? I know its pretty basic, but could someone give me some pointers?

- Joined

- Dec 27, 2014

- Messages

- 4,057

Use the side of the end mill, not the end, except at the bottom of the cut.

The only thing not stated so far is that the part needs to be square with the table. The vise is usually dial indicated in so it aligns with the X axis, (The long tee slots in the table). In your case a good carpenters' or machinist square should be sufficient. If you don't have a vise, you can place the part on a flat piece of wood for space and clamp to the table. You MUST clamp enough or provide for some way that piece can't turn if you take to deep of a cut. A piece of wood or metal in the tee slot should be enough. Push it up against it and clamp. If you have a vise, problem solved. Welcome to the forum.

If you do have a vise and dial indicator, tell us and we will walk you through the setup or recommend some videos.

If you do have a vise and dial indicator, tell us and we will walk you through the setup or recommend some videos.

- Joined

- Mar 21, 2018

- Messages

- 1,597

As Chewy says, setup is a fairly important step. I assumed that you would have known that, but perhaps it needs to be clarified.

If you don't have a good, solid vise for your mill, then you are going to have to use hold downs that use the T-slots (they come in sets). If you don't have either of these, then I suggest that you GET one or the other. The part must become one with the table for not only accomplishing your objective, but for safety reasons too.

Another option is to use a table saw with a good carbide tipped blade. It will cut aluminum all day long. It might even be easier to do on a table saw.

If you don't have a good, solid vise for your mill, then you are going to have to use hold downs that use the T-slots (they come in sets). If you don't have either of these, then I suggest that you GET one or the other. The part must become one with the table for not only accomplishing your objective, but for safety reasons too.

Another option is to use a table saw with a good carbide tipped blade. It will cut aluminum all day long. It might even be easier to do on a table saw.