- Joined

- Dec 6, 2012

- Messages

- 2,677

I'm not sure where to put this thread. It doesn't belong under: MACHINE PICKUPS & RIGGERS AVAILABLE & NEEDED As I'm not asking for help hauling merely best practice advise on securing a load.

Please note this excerpt:

Vehicles carrying objects that are not properly secured pose a safety risk on our nation's roadways. Debris that falls from a vehicle can collide with other vehicles or pedestrians, causing serious injuries or fatalities. According to data collected by NHTSA, there were about 440 fatalities caused by roadway debris in 2010. However, the exact number of incidents resulting from vehicles carrying unsecured loads is unknown.

http://www.gao.gov/products/GAO-13-24

This doesn't include the fact that you now have a damaged machine tool, truck, trailer, etc.

As we all tend to do things the way the we've seen them done, or we improvise. And those aren't necessarily best practice. Thus, the point of this thread is what is best practice for securing loads. Additionally, I need to take some of my 2dozen ratchet straps out of service due to some cuts in the webbing. I'm considering replacing with binders and am looking for direction on best purchase and application.

Ratchet straps?

`- are all grades of ratchet straps equal? (when should you use the 1inch or 2inch, when is rope enough?)

- how do you use a ratchet strap? (both securing hooks, wrapping machines, and the ratchet mechanism)

- when should straps be retired? How do you protect webbing from from sharp corners?

- What do you do with any left over tails?

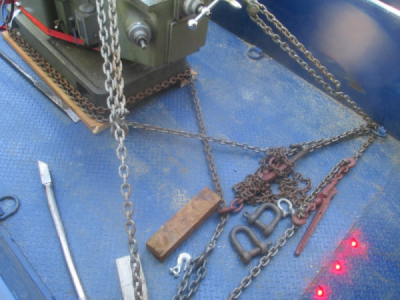

Load binders?

- from what I've read I need schedule 70 chain for securing and schedule 80 for lifting. It's likely that the many chains I already have are 43. Some of them should likely be destroyed due to damaged links.

- are all grades of binders equal?

- binders come as levers and ratchets. Is there a preference?

- how many do you need?

- how are they best used?

In this thread it's not my intent to explore loading or unloading. Nor the mechanics of truck & trailer drive-lines or tires. Merely how do we get it to stay.

I also understand that there are legal implications of this thread. The best official transportation document I've found is: https://www.fmcsa.dot.gov/regulations/cargo-securement/cargo-securement-rules If anyone finds something better. Please send a link!!

Thank you.

Daryl

MN

Please note this excerpt:

Vehicles carrying objects that are not properly secured pose a safety risk on our nation's roadways. Debris that falls from a vehicle can collide with other vehicles or pedestrians, causing serious injuries or fatalities. According to data collected by NHTSA, there were about 440 fatalities caused by roadway debris in 2010. However, the exact number of incidents resulting from vehicles carrying unsecured loads is unknown.

http://www.gao.gov/products/GAO-13-24

This doesn't include the fact that you now have a damaged machine tool, truck, trailer, etc.

As we all tend to do things the way the we've seen them done, or we improvise. And those aren't necessarily best practice. Thus, the point of this thread is what is best practice for securing loads. Additionally, I need to take some of my 2dozen ratchet straps out of service due to some cuts in the webbing. I'm considering replacing with binders and am looking for direction on best purchase and application.

Ratchet straps?

`- are all grades of ratchet straps equal? (when should you use the 1inch or 2inch, when is rope enough?)

- how do you use a ratchet strap? (both securing hooks, wrapping machines, and the ratchet mechanism)

- when should straps be retired? How do you protect webbing from from sharp corners?

- What do you do with any left over tails?

Load binders?

- from what I've read I need schedule 70 chain for securing and schedule 80 for lifting. It's likely that the many chains I already have are 43. Some of them should likely be destroyed due to damaged links.

- are all grades of binders equal?

- binders come as levers and ratchets. Is there a preference?

- how many do you need?

- how are they best used?

In this thread it's not my intent to explore loading or unloading. Nor the mechanics of truck & trailer drive-lines or tires. Merely how do we get it to stay.

I also understand that there are legal implications of this thread. The best official transportation document I've found is: https://www.fmcsa.dot.gov/regulations/cargo-securement/cargo-securement-rules If anyone finds something better. Please send a link!!

Thank you.

Daryl

MN