Many years ago I was a tank crew man in Germany. One of the most hair-raising duties was loading and securing the tanks on rail cars for transportation to training exercises.

View attachment 134451

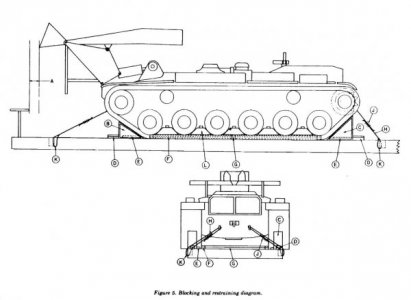

Please note that the bottom picture accurately depicts the situation - the treads hung over both sides of the flat bed cars by almost half. We had to drive down the line of cars that way until we got to our assigned spot.

Our M60 series tanks weighed 53 tons. The chain binders were equipped with turn buckles. The front and rear were blocked and the blocks were nailed down with 40d nails. Now I know that folks here are not likely to move anything that heavy. But the main reason for mentioning it is one little detail - using wire to secure the chain hooks:

View attachment 134453

"c. Chain Application. Vehicle chains are applied in pairs and parallel to each other. Do not attach chains in a vertical position. The angle between the chain and the car deck must not exceed 45 degrees when viewed from the side. Chains must not kink, twist, or cross. (The shackles and shackle mounts are not designed to be pulled from an oblique angle and thus will not hold their rated strength.)

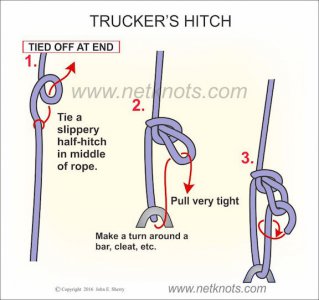

d. Chain Hooks. Chain hooks must be secured with wire. Wire must be passed through the chain link and the throat of the hook and fastened on the backside of the hooks (Figure 20-27). Do not apply wire around the open end of the hooks. Without the wire, the hook will fall off because of slack action during transit."

Have to add my two cents worth on the subject. As Charles has shown there is a right and wrong way for load securement, the military has their own set of procedures. I am familiar with most of the procedures being in the heavy haul truck business for 43 years. I have moved literally hundreds of M1-A1 Abrams heavy tanks for the army, more specifically the Texas Army National Guard. The Abram weighs 134,000 lbs. with the battle skirts installed.

Also moved drilling rigs for years, with some components weighing in excess of 100K and very top heavy.

All that being said, the main thing is if you don't know what you are doing, it is safer and maybe a whole lot cheaper in the long run , to employ someone with experience (and insurance). Top heavy loads are extra problematic, and require extra securement and dunage.

Some basic rules that apply:

1. Use separate securement devices whether (approved) nylon straps and hardware on

all four corners. I the cargo is very heavy, use chains and ratchet binders.

2. Use heavy dunage under load to spread load over larger footprint.

3. Make sure trailer is up to the task, tires, floor and super structure

4. DOT approved 4" straps will work for most loads, but be careful of sharp edges on cargo. Do not use frayed or cut straps.

5. Tall cargo, like a mill needs to be secured not only at the base but also higher up as well, they are top heavy.

6. Use good common sense, if it seems like it might not be safe, it probably isn't.

Be careful guys...