-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

[How-To] How would you?

- Thread starter finsruskw

- Start date

- Joined

- Sep 22, 2019

- Messages

- 940

Thanks Dave, That's what I did but two 2" holes one lower and one upper leaves an interrupted cut and I am tearing up my boring bars!

They are just the cheap brazed insert sets from you know where, bought used w/unknown sharpness.

They are just the cheap brazed insert sets from you know where, bought used w/unknown sharpness.

- Joined

- Apr 4, 2016

- Messages

- 853

I'm assuming that you intend to cut the straight sides joining the two arcs with a milling cutter ? If so, maybe if you cut out that section before using the boring head to enlarge those 2" holes it would reduce the severity of the interrupted cut. Just a thought.

Ted

Ted

Use 1/4 drill bit to Incremental rough drill out inside. Then use boring head to machine radius at both ends. Then use the same setting boring head to flycut the radial tangent sides @ .025” d.o.c. per pass. Preferably using a boring bar that takes inserts.

- Joined

- Sep 22, 2019

- Messages

- 940

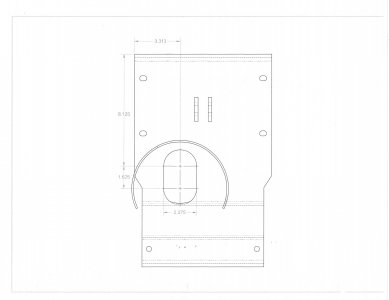

OK, I have the flat sides milled to correct width, 2.375.

This still leaves .1875 on the upper and lower ends.

Should I set the bar for the full 2.375 width and advance it with the X axis?

Or, should I start at 2" at the correct X?Y axis and keep adjusting the bar outwards?

This still leaves .1875 on the upper and lower ends.

Should I set the bar for the full 2.375 width and advance it with the X axis?

Or, should I start at 2" at the correct X?Y axis and keep adjusting the bar outwards?

I;m back in the tractor business fin , although green this time .

I;m back in the tractor business fin , although green this time .  Don't let that out over on OCC .

Don't let that out over on OCC .