-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

[How-To] How would you?

- Thread starter finsruskw

- Start date

- Joined

- Aug 19, 2023

- Messages

- 438

Three holes.. Center, Upper, then Lower. at least, that was what I was taught.....

- Joined

- Sep 22, 2019

- Messages

- 940

AS promised, film at eleven....or thereabouts!!Three holes.. Center, Upper, then Lower. at least, that was what I was taught.....

slow process, gotta be a better way

I have a regular hole saw set up to 2.5" by 1/4" increments, I may try that on the next one.

I have 4 of them to do.

So what if its 1/8" oversize!

Attachments

- Joined

- Jan 31, 2016

- Messages

- 11,448

I'll never tell !So what if its 1/8" oversize!

Whatcha making ?

Whatcha making ?- Joined

- Sep 22, 2019

- Messages

- 940

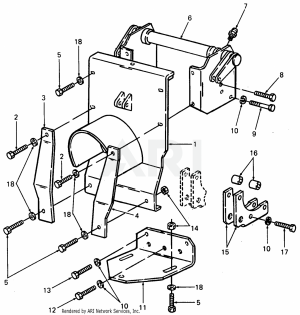

Couple of 383 Cat 0 kits.I'll never tell !Whatcha making ?

I have 2 of them sold