- Joined

- Dec 18, 2019

- Messages

- 6,447

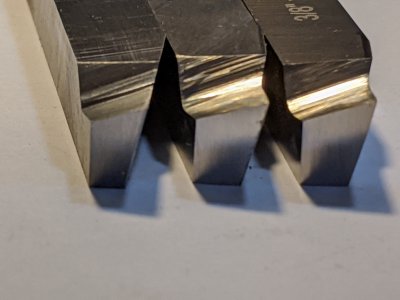

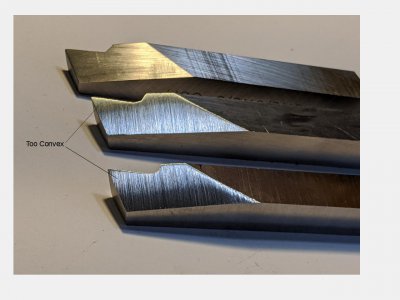

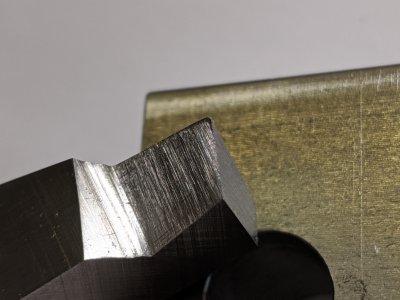

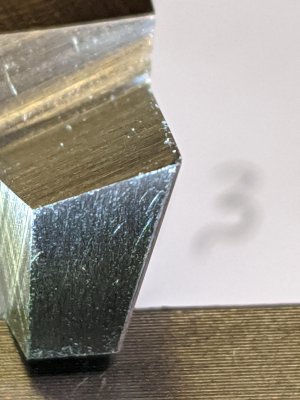

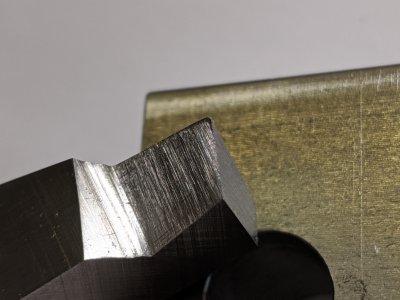

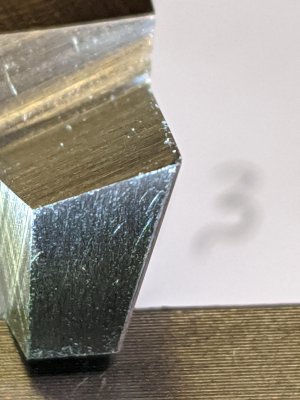

Here's a few. Gee, I didn't do a very good job on this tool. Un-doctored photos.

Looking at the last photo, the cutting edge (as used) has damage for 2mm out of the 5mm edge. (From the tip, then 2mm to the right.) I don't think that damage was present when I was done honing.

Looking at this with a critical eye, there's clearly stuff to fix. On my part, I will try to grind a new square bit from the same lot (no quenching of any sort) and maybe from some cobalt steel (also no quenching).

Looking at the last photo, the cutting edge (as used) has damage for 2mm out of the 5mm edge. (From the tip, then 2mm to the right.) I don't think that damage was present when I was done honing.

Looking at this with a critical eye, there's clearly stuff to fix. On my part, I will try to grind a new square bit from the same lot (no quenching of any sort) and maybe from some cobalt steel (also no quenching).