- Joined

- Sep 7, 2019

- Messages

- 674

Thanksgiving write up time! It's been a while since I shared a project so here goes!

Firstly, the impetus for this project was the meltdown of my TIG torch using a cobbled together cooler system. It was just a submersible pump in a bucket of water.

I believe the failure occurred due to improper plumbing of the lines. Based on the diagram for the torch (Weld Tec 20), the water is supposed to go from the pump to the torch via the dedicated water hose and return to the water tank via the power cable. I had it backwards with the water going TO the torch via the power cable. In this way the water is being heated up the entire time it is en-route to the torch head, couple this with my pump's anemic flow capability and a high amp setting, and the water likely boiled in the torch head and burst the hose at the weakest point by steam pressure. At least that's what I think happened.

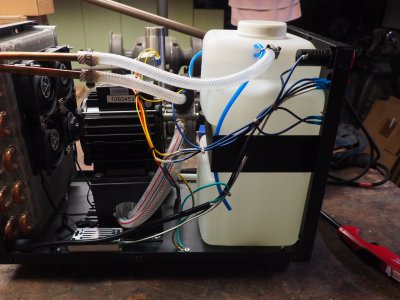

I then decided it was time to step up and get a proper cooling system. I weld only occasionally for hobby purposes but I like doing it and I want it to work properly when I need it to. I looked around the net and settled on the HTP Arctic Chill 5460. The coolers from Weld Tec were very nice but also very expensive, like $900! I kind of wanted to avoid cheaper unbranded ebay coolers as well. At the time HTP had a demo model on sale in the clearance section of their site for about $380, so the savings were decent over a brand new one. And I like that I can contact HTP for service/support if needed.

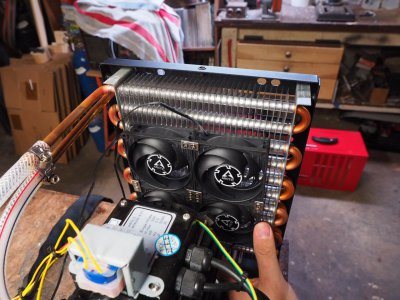

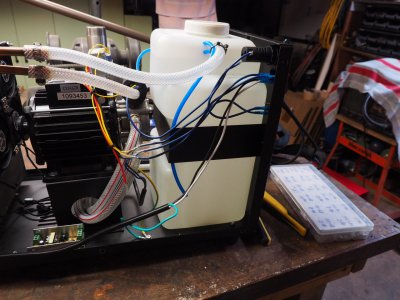

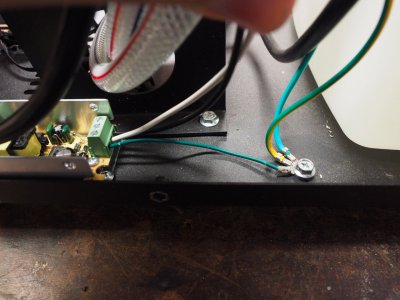

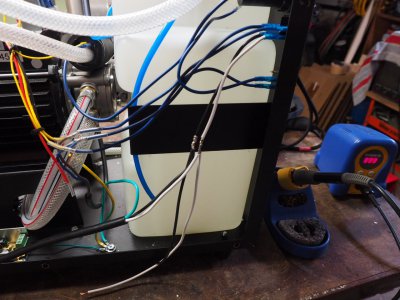

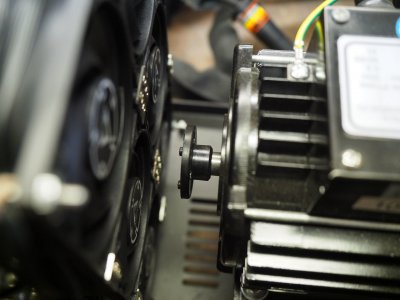

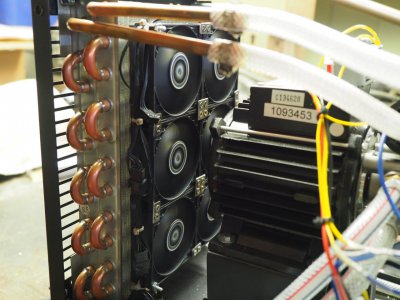

So I got the thing, filled it with distilled water and a splash of the recommended lube/algaecide (also from HTP), and hooked it up to a new torch. I was a little disappointed in the noise level. I work in a small corner of a basement, it's maybe 100 square feet so it's nice if I could keep the noise level down while in the shop. I ran across a video from YouTuber This Old Tony a few months ago about this very issue so I re-watched it and got inspired to do a similar mod. The vid is below if you care to watch it, but basically he replaces the mechanical fan with a group of 12V case fans, like you'd use on a computer.

Thus motivated by TOT's work, I ordered up some parts!

More to follow...

Firstly, the impetus for this project was the meltdown of my TIG torch using a cobbled together cooler system. It was just a submersible pump in a bucket of water.

I believe the failure occurred due to improper plumbing of the lines. Based on the diagram for the torch (Weld Tec 20), the water is supposed to go from the pump to the torch via the dedicated water hose and return to the water tank via the power cable. I had it backwards with the water going TO the torch via the power cable. In this way the water is being heated up the entire time it is en-route to the torch head, couple this with my pump's anemic flow capability and a high amp setting, and the water likely boiled in the torch head and burst the hose at the weakest point by steam pressure. At least that's what I think happened.

I then decided it was time to step up and get a proper cooling system. I weld only occasionally for hobby purposes but I like doing it and I want it to work properly when I need it to. I looked around the net and settled on the HTP Arctic Chill 5460. The coolers from Weld Tec were very nice but also very expensive, like $900! I kind of wanted to avoid cheaper unbranded ebay coolers as well. At the time HTP had a demo model on sale in the clearance section of their site for about $380, so the savings were decent over a brand new one. And I like that I can contact HTP for service/support if needed.

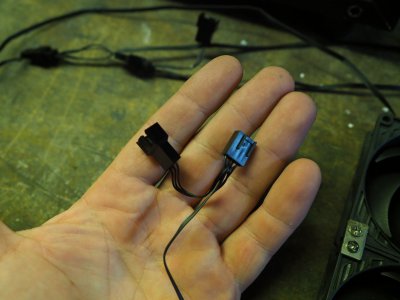

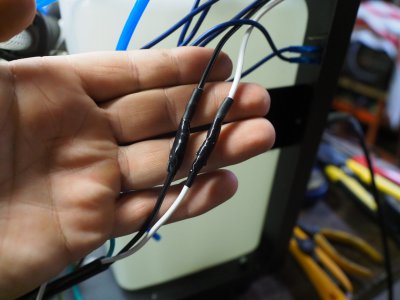

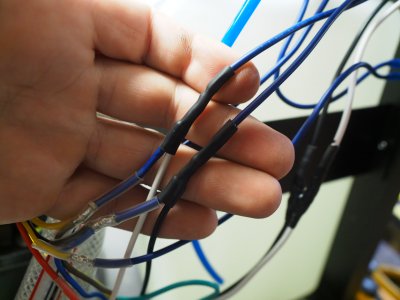

So I got the thing, filled it with distilled water and a splash of the recommended lube/algaecide (also from HTP), and hooked it up to a new torch. I was a little disappointed in the noise level. I work in a small corner of a basement, it's maybe 100 square feet so it's nice if I could keep the noise level down while in the shop. I ran across a video from YouTuber This Old Tony a few months ago about this very issue so I re-watched it and got inspired to do a similar mod. The vid is below if you care to watch it, but basically he replaces the mechanical fan with a group of 12V case fans, like you'd use on a computer.

Thus motivated by TOT's work, I ordered up some parts!

More to follow...