-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I need a pneumatic thingamabobby!

- Thread starter lesrhorer

- Start date

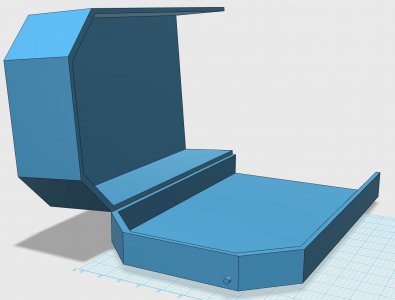

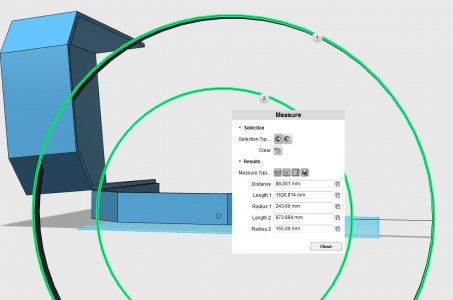

The strut I will be using has a maximum extension of 245mm and a minimum compression of 155mm. I used a number of 243mm just to make sure the lid would open to AT LEAST 95 degrees. I created two hollow cylinders, one with a radius of 155mm and the other with a radius of 243mm both centered on the strut attachment pin. When fully open, the strut attachment cannot sit outside the larger circle, and when closed, it cannot lie inside the smaller circle.

Attachments

Last edited:

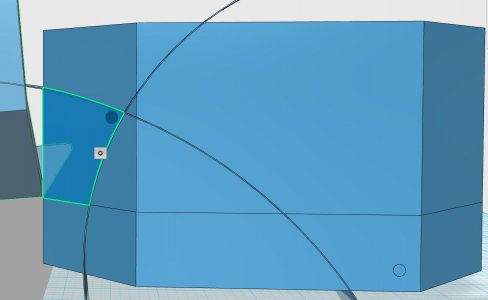

I attached the larger cylinder to the open lid so it moves along with the lid. Then I made a copy of the lid with the attached cylinder and rotated it into the closed position. The attachment pin must lie somewhere between the two cylinders as shown below.

Attachments

The closer to the upper cylinder, the further the strut will extend, increasing the mechanical advantage. The closer to the lower cylinder, the further the strut will close, also increasing the mechanical advantage. The maximum possible mechanical advantage will be achieved if the strut is mounted precisely at the intersection of the two cylinders. Even though I had already allow 2mm headroom in the extension, I placed the strut about 4mm further within the strut's functional range just to be safe.

While those locations work just fine to stop the lid from opening too far, the strut(s) will still be trying to push the lid open when it's closed. If they're weak enough it shouldn't open on it's own but, it may rattle. Ideally, gas struts are mounted so the pivot points travel slightly over center (relative to the hinge) so they hold the lid/door closed as well as open.

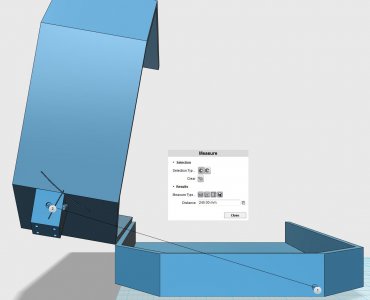

Correct. Unfortunately, however, There isn't quite enough room. The region to the right of the current position is taken up by the spindle switch. (See below.} I could possibly have gone with a shorter strut, I suppose, but this mill has a lid lock that holds the lid shut securely in any case, so it's not a big deal. I am going to try moving the mobile hard point up a bit, which will not only lower the angle and reduced the lifting force, but will also prevent the lid from falling over when opened, as it does now. The moveable strut pin is currently set at the mid-point of the lid edge. I am going to move it up by roughly 1/2".While those locations work just fine to stop the lid from opening too far, the strut(s) will still be trying to push the lid open when it's closed. If they're weak enough it shouldn't open on it's own but, it may rattle. Ideally, gas struts are mounted so the pivot points travel slightly over center (relative to the hinge) so they hold the lid/door closed as well as open.

I am not quote certain what you mean. Perhaps you might provide a drawing? If one draws a line from the hinge pin to the fixed strut pin, then in order to push the lid closed the moveable strut pin must be placed below the line. This cannot be accomplished if both strut pins are mounted directly on the mill head and mill lid, respectively. As far as I can see, in practical terms, this means mounting the fixed pin above the mill head using some sort of extension plate. No matter where this would be placed, the strut would be in the way. Here is the current mounting:Perhaps, if you mounted the lid mount further away from the lid, it would cam over and hold shut?

As mentioned above, I think I am going to move the upper strut pin up about 1/2", to prevent the lid from moving to the point where its center of mass is to the left of the hinge. This causes the lid to "flop" over against the strut limit rather aggressively. With the strut pin in the proposed position, the lid will always be applying a small compressive force on the strut, rather than trying to suddenly pull it apart.

Last edited: