If you let me know what thread you want to cut and what TPI your leadscrew is i can do you a sketch showing how to set up the gears. It can seem daunting but i'm pretty sure if someone explains/shows you it'll all fall into place.

If i can help i will !

Mike Young

OK. I think I understand how the chart works. Unfortunately I don't think it will work for this lathe.

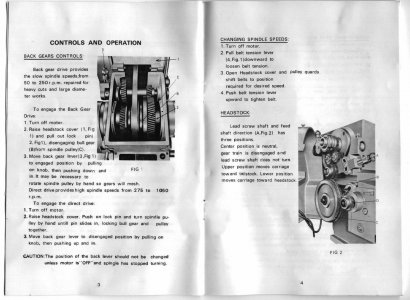

You see, It's a clone of the Jet/Enco 1024. This lathe has an 8TPI leadscrew, but also uses a quick change gear box, and only three change gear positions. I bought this lathe used, without the optional metric change gears, therefore it only has the stock inch change gears in it. This consists of a 40 tooth drive gear, 70 tooth intermediate gear and a 40 tooth driven gear on the leadscrew gearbox. The intermediate gear I have is a single pattern, but the optional gearset for this position is actually a compound gear with a 120 and 127 tooth gears in it. I have attached a photo of the gear set/quadrant to illustrate better. Page 4, figure 2 shows B, C and D as "tumbler" gears. Those are the change gears.

Since I don't have ANY extra gears for this, I can not use the system you linked for me. My only choice appears to make the compound gear set.