- Joined

- May 13, 2019

- Messages

- 1,016

Hi all,

I've been looking for a first project that involves cutting gears and I found one. I'm a homebrewer and want to build a bench bottle capper. I know I could buy one cheaper, but I want a project involving gears.

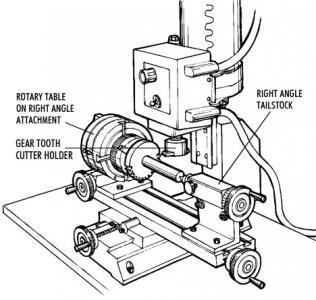

I've been designing this in FreeCad, but I'm not sure what gear parameters I should use. I have a PM25 mill and dividing head. I plan on buying the rack since I don't have the tools to make a long (~12") rack. I want to only cut the pinion.

Questions:

As to formulae, assuming DP20, N=24:

OD = (N+2)/DP = (24+2)/20 = 1.300"

I see some differences when calculating the depth of cut depending on the PA:

From "Gears and Gear Cutting" by Ivan Law:

Depth of cut = 2.157/DP = 2.157/20 = 0.1079"

From Machinery's Handbook, 25th edition (page 1930):

Minimum Whole Depth = 2.157/DP = 2.157/20 = 0.1079" for PA=14.5

From Machinery's Handbook, 25th edition (page 1925):

Whole Depth (preferred) = 2.250/DP = 2.250/20 = 0.1125" for PA=20

All comments would be appreciated.

I've been looking for a first project that involves cutting gears and I found one. I'm a homebrewer and want to build a bench bottle capper. I know I could buy one cheaper, but I want a project involving gears.

I've been designing this in FreeCad, but I'm not sure what gear parameters I should use. I have a PM25 mill and dividing head. I plan on buying the rack since I don't have the tools to make a long (~12") rack. I want to only cut the pinion.

Questions:

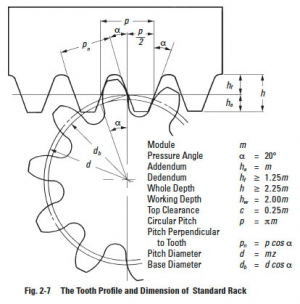

- Should I use imperial (DP) or metric (module)? Metric cutters seems slightly easier to obtain?

- What pitch should I use?

- How many teeth?

- Pressure angle = 20 or 14.5? PA=20 seems to be for new designs?

As to formulae, assuming DP20, N=24:

OD = (N+2)/DP = (24+2)/20 = 1.300"

I see some differences when calculating the depth of cut depending on the PA:

From "Gears and Gear Cutting" by Ivan Law:

Depth of cut = 2.157/DP = 2.157/20 = 0.1079"

From Machinery's Handbook, 25th edition (page 1930):

Minimum Whole Depth = 2.157/DP = 2.157/20 = 0.1079" for PA=14.5

From Machinery's Handbook, 25th edition (page 1925):

Whole Depth (preferred) = 2.250/DP = 2.250/20 = 0.1125" for PA=20

All comments would be appreciated.