- Joined

- Jan 18, 2018

- Messages

- 314

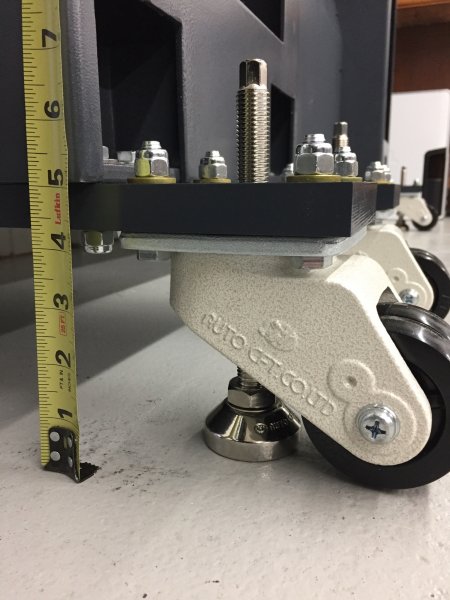

Waverly, I have a 1236-T and am the same height. This was my solution:

It has been solid, mobile and easily adjustable. If interested search for thread “Setting-up the PM 1236-T” here on H-M and look at posts 20 through 32 for details. Good luck.

It has been solid, mobile and easily adjustable. If interested search for thread “Setting-up the PM 1236-T” here on H-M and look at posts 20 through 32 for details. Good luck.