Please excuse my ignorance when it comes to Carbide Inserts.

I recently upgraded from the 12x36 Tida to a Birmingham 1440g and want to also upgrade from HSS to insert type holders and carbide.

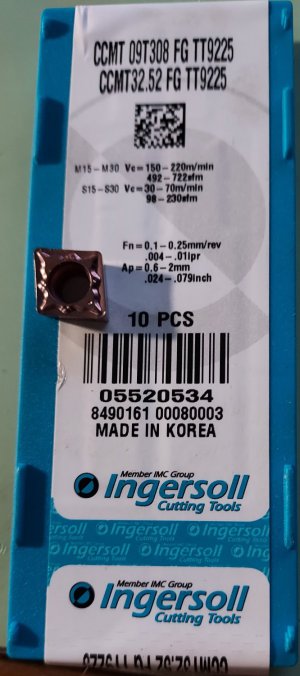

There are so many different shapes of inserts.

Are there advantages to one shape over another?

I only want to buy a couple of insert holders at first.

Is there a place here or elsewhere that explains suggested uses for the different holders and inserts?

Gary

I recently upgraded from the 12x36 Tida to a Birmingham 1440g and want to also upgrade from HSS to insert type holders and carbide.

There are so many different shapes of inserts.

Are there advantages to one shape over another?

I only want to buy a couple of insert holders at first.

Is there a place here or elsewhere that explains suggested uses for the different holders and inserts?

Gary