- Joined

- Nov 28, 2016

- Messages

- 2,406

In response to a question that I was asked on the 'what did you buy today' thread, I decided to do a pictorial thread on indicating a 3 jaw independant scroll chuck. The reason for this thread is both to keep form hijacking the other thread too much, and also to make this easier to find if someone else needs it in the future.

To begin, a 3 jaw independant scroll chuck is like a standard 3 jaw, it has a scroll which moves all 3 jaws together and keeps them somewhat centered, but the jaws are 2 piece jaws, making them independantly adjustable. My Rohm chuck is older and has some wear, so it will only repeat within about .005-.007 using the scroll to tighten.

First, I put the part in and tighten using the scroll...

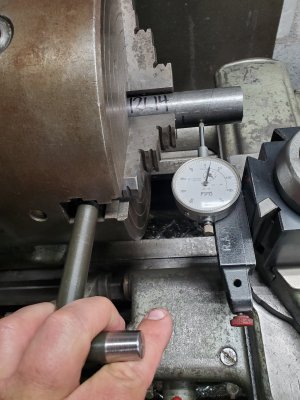

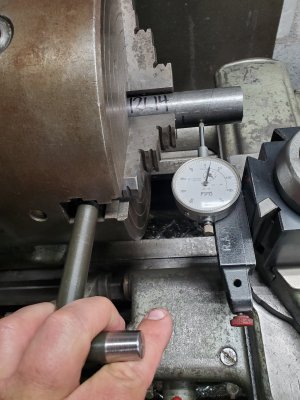

Next, I put the indicator on the part. I use a travel indicator mounted on a magnetic base that I just stick to the side of the QCTP.

I rotate the chuck and stop with the indicator even with all 3 jaws and note the readings. Here, jaw #1 is at 0.000...

Jaw 2 is at 0.010...

And jaw 3 is at 0.004...

Now, I go to the lowest jaw (#1) and loosen the adjuster on that jaw about ⅓ of the runout (0.003)...

Now I check all 3 jaws again. #1 is at 0.003, #2 is at 0.009, # 3 is at 0.001.

Now I will go to the high point, (jaw #2) and tighten it about ⅓ of the runout (0.003).

Now jaw #1 is at 0.007, #2 is 0.006, #3 is 0.001. I'll go to the low point (#3) and loosen it about 0.003.

I will continue to alternate between the high point and low point, tightening and loosening as necessary until I get it running as close as I need it.

If you turn the scroll at all during this process, you will probably have to start over... do all the adjusting with the jaw adjustments.

I can usually get it within a half thousandth of an inch in a minute... 2 minutes tops... but I've been doing this for a couple of years

Finished...

Jaw #1...

Jaw #2...

Jaw #3...

It's really simple and quick once you get used to it. I hope this helps someone...

-Bear

To begin, a 3 jaw independant scroll chuck is like a standard 3 jaw, it has a scroll which moves all 3 jaws together and keeps them somewhat centered, but the jaws are 2 piece jaws, making them independantly adjustable. My Rohm chuck is older and has some wear, so it will only repeat within about .005-.007 using the scroll to tighten.

First, I put the part in and tighten using the scroll...

Next, I put the indicator on the part. I use a travel indicator mounted on a magnetic base that I just stick to the side of the QCTP.

I rotate the chuck and stop with the indicator even with all 3 jaws and note the readings. Here, jaw #1 is at 0.000...

Jaw 2 is at 0.010...

And jaw 3 is at 0.004...

Now, I go to the lowest jaw (#1) and loosen the adjuster on that jaw about ⅓ of the runout (0.003)...

Now I check all 3 jaws again. #1 is at 0.003, #2 is at 0.009, # 3 is at 0.001.

Now I will go to the high point, (jaw #2) and tighten it about ⅓ of the runout (0.003).

Now jaw #1 is at 0.007, #2 is 0.006, #3 is 0.001. I'll go to the low point (#3) and loosen it about 0.003.

I will continue to alternate between the high point and low point, tightening and loosening as necessary until I get it running as close as I need it.

If you turn the scroll at all during this process, you will probably have to start over... do all the adjusting with the jaw adjustments.

I can usually get it within a half thousandth of an inch in a minute... 2 minutes tops... but I've been doing this for a couple of years

Finished...

Jaw #1...

Jaw #2...

Jaw #3...

It's really simple and quick once you get used to it. I hope this helps someone...

-Bear

Last edited: