- Joined

- Jan 28, 2020

- Messages

- 193

Yes, it helps.You are correct that the specific tool recommendations in the book are for medium sized (10-14") lathes. There are indeed smaller 3/8" and maybe even some 1/4" shank tools that are equivalent to those recommended in the book.

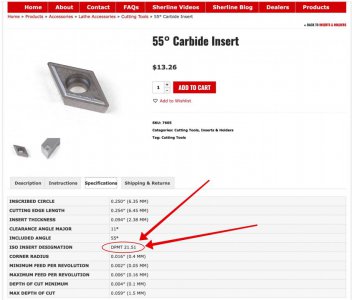

I just looked at the Sherline indexable tool offerings, and the specs are all for positive inserts CPMT, DPMT, etc. which have an 11° relief angle and a 0.250" I.C. and appear to be industry standard. Their turning/facing toolholders are not sufficiently specified to know precisely if they are neutral or positive rake, and the lack of industry standard nomenclature suggests to me that the Sherline toolholders are proprietary.

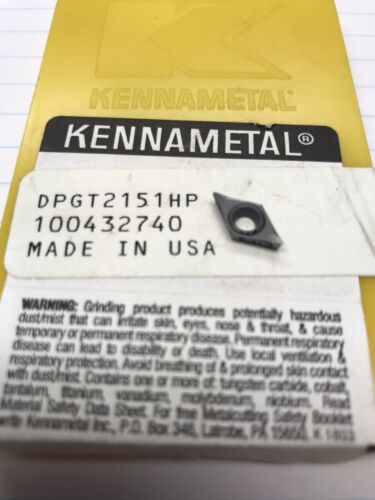

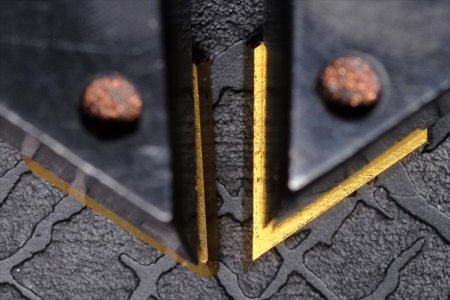

For the Rhombus (80°) CPMT21.5 type inserts Sherline sells, the industry standard turning/facing toolholders would be designated SCLP such as the 3/8" square shank Kennametal 1095594 (right hand) and 1095686 (left hand), both of which mount the insert at a positive 5° rake angle. So it's likely the Sherline toolholders mount the CPMT inserts at a positive rake also. Below is the drawing for the Kennametal equivalent toolholder - you can clearly see the positive rake mounting. The positive rake puts less demand on the required HP of the machine and should be freer cutting than a neutral rake holder which is probably why Sherline chose this geometry and positive rake insert type.

View attachment 392407

That said, quality of finish will have a lot to do with the specific insert, nose radius, etc. The Sherline inserts are CPMT21.51 with a 0.016" nose radius which is why they spec a minimum depth of cut of 0.004". Sherline says this about their inserts:

"Carbide cutters give good finishes on hard-to-machine materials such as cold-rolled steel. They will also work on aluminum, brass, or leaded steels, and will last practically forever. However, the best finishes on those materials are still achieved with a good, sharp high-speed steel tool."For the sharpest insert cutting edge you'd want a CPGT insert rather than a CPMT which Sherline doesn't offer, hence their admonition about using HSS on softer materials. The difference between the two types is covered on page 23 in the book and relates to the tolerance. The "G" tolerance is the most constrained and the inserts are typically ground to meet that tolerance spec, and thus will have a sharp (rather than blunt) cutting edge. The Iscar 5510088 would be an excellent CPGT21.50 (0.004" nose radius) insert for semi- and fine-finishing turning with a wide variety of materials including aluminum. And because of the smaller nose radius, minimum depth of cut would also be less - perhaps as low as 0.0015".

Hope this helps.

David Best

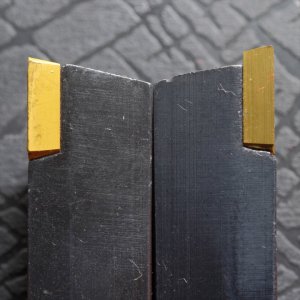

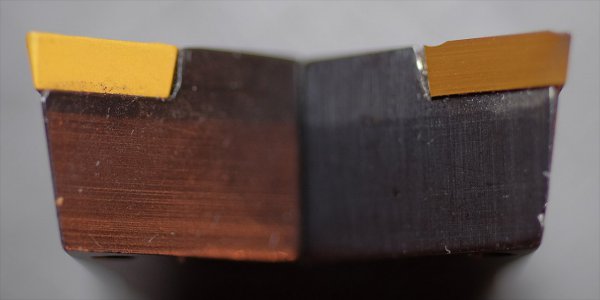

I have the Sherline 55° diamond-style right-hand and left-hand toolholders. I have not read any statement by Sherline that the inserts mount with a positive rake. From using squares to look for an angle, I concluded that the inserts do NOT mount with a positive rake angle.

I looked at the cutting edges of the of my DPMT 21.51 inserts from Sherline, using a 7x loupe. The edges appeared surprisingly rough.

Thank you for the 80° rhombus-style toolholders and insert recommendations for Sherline lathes.