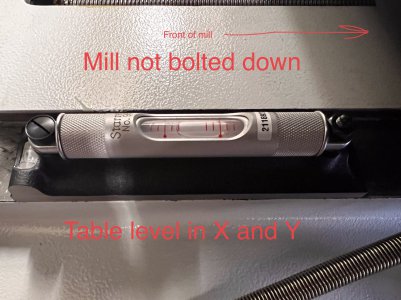

Any thoughts regarding spending the extra money to get a bench top mill hand scrapped? The dove tail ways for the saddle on my Taiwan built machine leaves a lot to be desired.

I have called and talked with Dans Machine Tool in Anaheim California. They can and will do the work for an estimated $3200 and about 4 weeks time.

To be clear, if I had the room I would have purchased a Bridgeport, but I don’t so I bought a new Taiwan manufactured bench mill.

Yes, I will only be doing hobby type work with it but……….

Thanks for your input

Art

I have called and talked with Dans Machine Tool in Anaheim California. They can and will do the work for an estimated $3200 and about 4 weeks time.

To be clear, if I had the room I would have purchased a Bridgeport, but I don’t so I bought a new Taiwan manufactured bench mill.

Yes, I will only be doing hobby type work with it but……….

Thanks for your input

Art