- Joined

- Aug 2, 2020

- Messages

- 564

The bottom of this little cabinet is rusted/ rotted very badly.

I would like to cut off the bottom 4" and replace it with new metal.

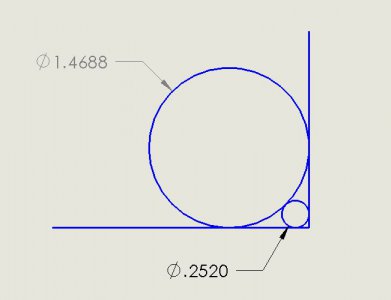

The corners are radiused and I would like to duplicate them. I first would look for some pipe or tubing the right outside diameter and cut pieces to make the round corners.

If I can't find something off the shelf I will make a die and do it in the press.

The sides of the cabinet are made of 10 ga steel. Yes, heavy stuff.

I could match something after I cut the bottom off but would be glad to have the rounded corners made before I start the project.

I know, I know, it is a fool's errand to try to save this old shaper cabinet but I would like to give it a try.

So how how to measure the radius now?

Thoughts?

Cabinet is upside down in the photo.

I would like to cut off the bottom 4" and replace it with new metal.

The corners are radiused and I would like to duplicate them. I first would look for some pipe or tubing the right outside diameter and cut pieces to make the round corners.

If I can't find something off the shelf I will make a die and do it in the press.

The sides of the cabinet are made of 10 ga steel. Yes, heavy stuff.

I could match something after I cut the bottom off but would be glad to have the rounded corners made before I start the project.

I know, I know, it is a fool's errand to try to save this old shaper cabinet but I would like to give it a try.

So how how to measure the radius now?

Thoughts?

Cabinet is upside down in the photo.

butt you have a 2mm pencil & the requisite soft 2mm leads laying around & you can just make a rubbing with the lead against both flat surfaces. Think I might be one of the last engineers to be taught manual drafting in college)

butt you have a 2mm pencil & the requisite soft 2mm leads laying around & you can just make a rubbing with the lead against both flat surfaces. Think I might be one of the last engineers to be taught manual drafting in college)