- Joined

- Nov 25, 2015

- Messages

- 8,320

Take 2 combo squares and put them on the case move them to where the flat starts to roll away the same on the other corner. Read the radius from where they meet. They should both read the same

How accurate? .001. .010, .05?

Put a square up to the corner and measure from corner to tangent point of arc.

Get a set of female radius gauges.

Don't work.Add the width to the depth of the cabinet and multiply by 2 to get the perimeter if it had square edges. = A

Measure with a flexible tape the actual perimeter. = B

A -B = Circumference of all 4 rads.

Divide by 2pi = average radius of all corners.

Sorry to post what at first seemed logical without checking first. Thanks for checking.Don't work.

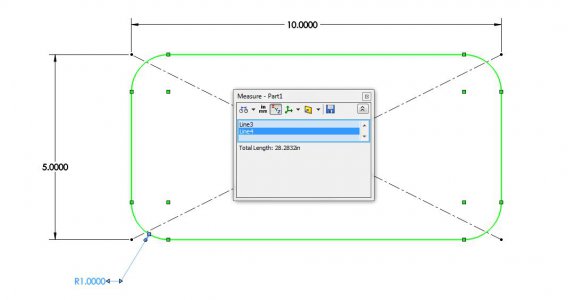

I laid out a 5" x 10" rectangle with 1" fillets The perimeter of the rectangle is 30". The perimeter of the filleted rectangle is 29.2932". The difference is 1.7168" and divided by 2π = .2732".

View attachment 452878

Edit: The straight sections on the sides A and B are A-2R and B-2R for a total length of 2(A+B)-8R. The four fillets form a compete circle of circumference 2πR. The total length of the perimeter of the filleted rectangle is 2(A+B) -8R + 2πR. The difference between the unfilleted and filleted rectangles is D = 8R - 2πR. Factoring out R and solving for R, R = D/(8 - 2π) = D/1.7168 = .5825D.