-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is There Anywhere To Trade Tools?

- Thread starter Scoutdawg

- Start date

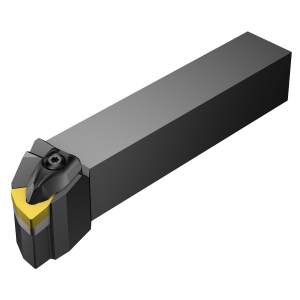

If I'm looking at the picture correctly, what you are lining up to is the carbide seat that the cutting insert sets on. Still have to lower the holder down to the tip of the insert.

X2

This gray seat supports the actual carbide insert and does no cutting. Do you have any inserts? Print on the side of holder should provide information.[/QUOTE]

See the above

- Joined

- Feb 7, 2011

- Messages

- 5,039

Okay. So the carbide insert that comes in the tool is actually not the cutter?

Sent from my LG-D959 using Tapatalk

Correct the seat should be held in with a screw then the insert clamps on top.

- Joined

- Apr 23, 2013

- Messages

- 1,014

This is almost the max diameter that the slot will allow. It is already bigger that the t that comes on the quick change tool post. I like using the 1 bolt as so I can rotate the tool holder.

Sent from my LG-D959 using Tapatalk