- Joined

- Mar 26, 2018

- Messages

- 2,724

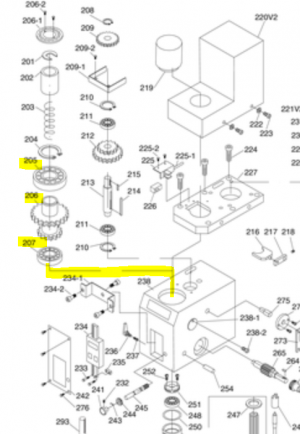

Sorry for the delayed response. This will be a tad confusing because I have modified my G0704 spindle for belt drive w/o quill function. You are correct that I am replacing the upper drive tube (items 205-207 in image below). The main difference is that my spindle is driven by a pulley on the spindle itself now rather than through the spline. This new tube simply supports the long and skinny spindle for the radial loads of the belt, and minimizes radial runout of the pulley. I have the option to mount an encoder to this assembly, so there is a plastic spline disc to transmit a small amount of torque to this tube (just to prevent them slipping relative to each other) but no cutting load will be seen by this assembly. Additionally, the spindle floats axially in this new assembly so no thermal growth will add axial loading to the bearings. This new assembly was needed to downsize the bearings to reach the 10,000rpm drive speeds desired.I want to make sure I am understanding what this part does, I took a look at the parts manual on the Grizzly site and it looks like you are making a new part to drive the spindle spline that will be connected to the motor? If so, then yes an H6 fit would likely be proper for the application since you will have a point load from the motor torque on the housing. Since you are using a CN bearing, I would not want to have interference in the fit that would compress the outer ring after installation, and the point load should keep it from spinning in the housing.

The limiting speed you referenced in a comment above can be higher or lower than what is stated in the bearing catalog and is based on the actual load conditions. The number in the catalog is for a standardized condition and there are adjustment factors for your actual conditions. Do you have a way to install a temperature sensor in the housing so it directly measures the outer ring? The limiting speed assumes 70C outer ring temperature. The standard also assumes a load of 5% of the static rating of the bearing and an ambient temperature of 20C.

Once you get this running, I would run it in in stages to see how the temperatures go to make sure you don't seize a bearing. If the temperature runs away too quickly, it can lock the bearing and do a good bit of damage. If you find the temperature is getting too high, you might need to use C3 bearings in this application.

The Explorer bearings Beckerkumm mentioned are similar to FAG X-Life bearings that are made to P6 standards and are smoother running and can carry a higher load than standard bearings without much added cost, so if the size you are using is available in that series, it is a good idea to go with those.

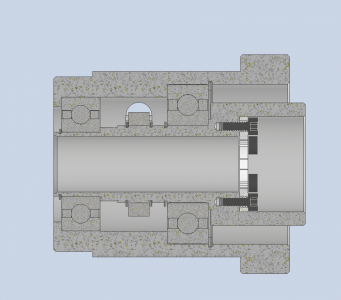

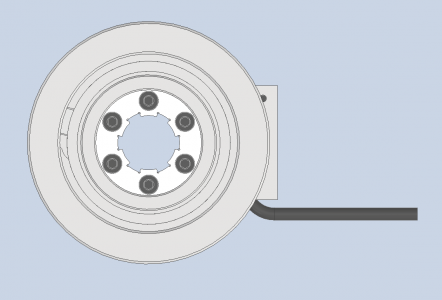

Since the new bearings are smaller than the stock bearings, There is an outer housing to create the needed fit between the bearings and the bores in the existing housing. The entire assembly looks like this:

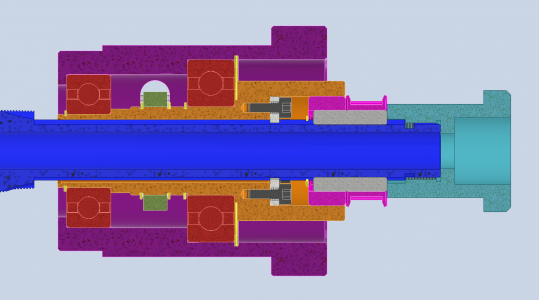

Here is a colored coded assembly diagram. I've already machined the orange shaft, and I'm working on selecting the final fits for the purple housing.

I think a looser fit for the housing seems to be appropriate. H6 seems to be that fit, but I have no experience in this.

I'll price out those bearings! Thanks for the info.