- Joined

- Jan 26, 2021

- Messages

- 344

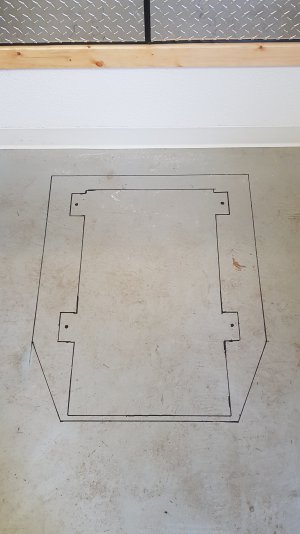

I was thinking leave the plastic cut back an inch or so all the way around so it's not visible. I'd definitely want to add anchor bolts so I could physically connect the machine base to the new concrete base. One small issue is the leveling tabs on the base are threaded. I suppose I could drill them out.Your cement floor looks to be nice and smooth in the photos. Maybe just use shoe polish wax instead of the plastic as a potential release agent. The edge of the plastic sticking out would not look so good to me.

Also consider topping the new cement pad with a layer of self leveling cement.

I imagine that you have already thought of anchor bolts.