- Joined

- Feb 29, 2016

- Messages

- 10

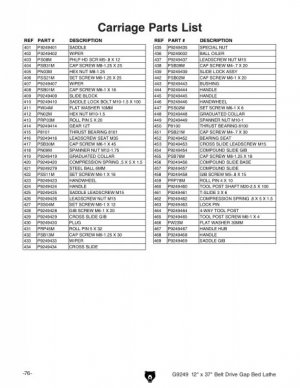

I just purchased a jet 12236 PS. I have disassembled it to clean it. I'm looking for documentation on it. Specifically a parts breakdown and any other information.

In addition the crossfeed leadscrew has significant backlash and I would like to replace it and nut if it all possible. Does anyone have any information on what the thread is. Is it an ACME standard or metric?

I contacted Jet and they had a little to no information.

Regards,

Jeff

In addition the crossfeed leadscrew has significant backlash and I would like to replace it and nut if it all possible. Does anyone have any information on what the thread is. Is it an ACME standard or metric?

I contacted Jet and they had a little to no information.

Regards,

Jeff