Hi Guys,

I hope that you all had a Merry Christmas and happy New Year!

The lathe is coming together pretty nicely. Everything is together and working now, just a few small things to take care of. Here are some pictures of the progress.

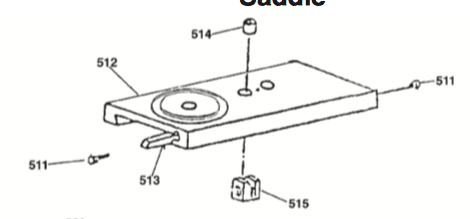

Parts came in came in from Grizzly, complete compound rest assembly, cross slide feed nut and carriage lock. I wasn't too happy with the quality of the compound, it had lots of rough edges and it had a black gritty oil on everything. I ended up taking the whole thing apart, cleaned everything and smoothed out the rough edges. It feels pretty good now.

Test fit the compound. It fits perfectly and the center height is right where it should be.

The captive nuts were $5 each from Grizzly, so I decided to make them myself. It's hard to get a nice surface finish on the old Champion blower and forge lathe, but they work fine.

The screw hole to mount the feed nut to the cross slide was larger than the screw used by the G9249, so instead of drilling and taping the feed nut, I decided to make a sleeve so that the smaller screw would fit.

I epoxied the Turcite to the cross slide, I haven't done any scraping yet since I don't have a surface plate yet, but as is, it fits and slides very nicely. One thing that I missed though, I didn't put any Turcite on the bottom of the gib, without it, it wants to fall down when I loosen the adjustment screws. It's okay for now, I just need to pry up on it slightly before tightening down the screws. I do have some pieces left that I will epoxy on soon and then it will not be an issue. I also need to make a new gib screw, the person that I purchased the cross slide from must has broken or lost one and they replaced it with a hex bolt and a plumbing fitting.

All together! Everything works as it should and is nice and tight.

Thank you everyone for your help and suggestions!

Kyle