This is like saying should I buy a Ford or Dodge 1/2T truck. Both distributors off several different versions of 1740 lathes, w/o being more specific and to indicate what use conditions and if you have 3 phase power/RPC it is hard to give an opinion, and/or alternatives. Many of these are available with inverter drives, usually the 5Hp models can be run on single phase, the larger 7.5 and 10 Hp models most likely not. If you do not have 3 phase power, than you would need to add in the cost of a 15/20Hp RPC, or a Phase Perfect solid state phase converter. Price wise, that adds another 2-3K to the costs. Cost of the VFD lathe versions is similar to the cost of an RPC or Phase Perfect.

I believe the economy versions of these lathes are form mainland China, the higher end models are Taiwanese manufactired.

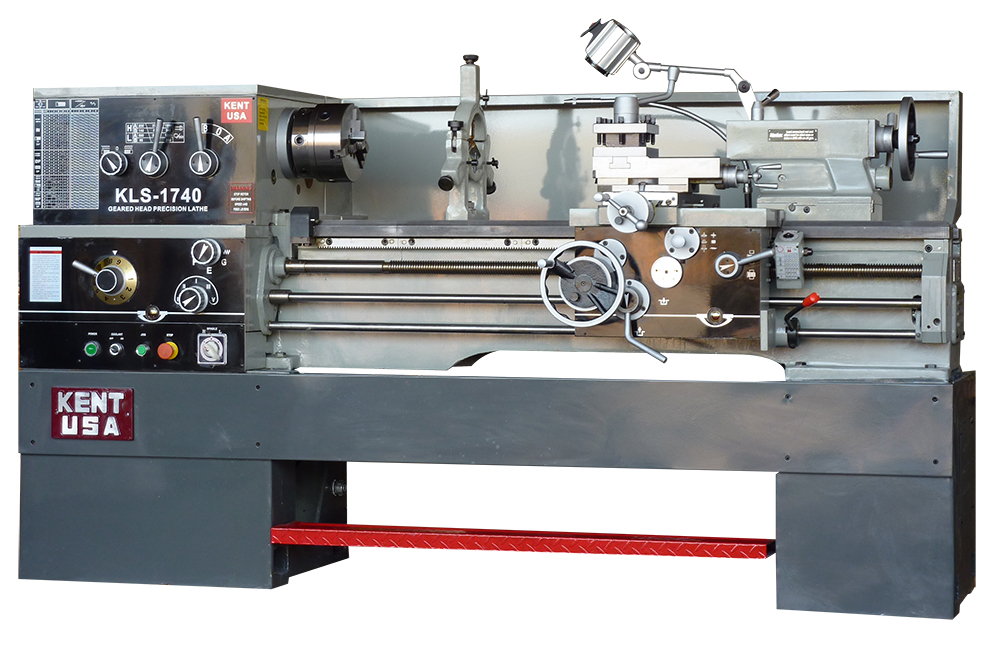

7.5 HP (10 HP on MLX model) Spindle Motor, 12-Speeds 3.125” Spindle Through Hole Solid Full-Length Casting Base with Front Loading Chip Tray for Easier Cleaning Adjustable Over-load Feed Clutches Quick Reversal Feed from Apron Full-length Safety Foot Brake Spindle Jog Button Control...

www.kentusa.com

6 HP main spindle motor 12 speeds, all geared headstock Hardened and ground gears and bedways Centralized lube system in headstock Cast iron machine bedways and base Removable chip pan for easy clean up Foot brake and T-Slot compound Inch/metric ruler on tailstock quill ISO 9001...

www.kentusa.com

victormachines.com

www.victormachines.com

www.victormachines.com

I am more partial to the Kent lathes, mostly because most of their higher end versions are made by Sunmaster lathes, which are very well made and fall into the light industrial range. Parts and service would be more available vs. some of the one off brand/one off imported model lathes that may disappear in a few years. I would also look at Vendor support.

The 5 and 7.5Hp versions are D1-6 chuck mounts, so a spindle bore in the 2.1-2.5" range, the 10Hp would be a D1-8 which gets you in the 3.1" range, cost of chucks and tooling also go up proportional to the size and Hp. My recommendation would be the Kent RML-1640T, RML-1660VT, ML-1740T, MLX-1740. The same models/lathe are sold by other distributors which may offer better pricing and/or support. I own a Sunmaster lathe, and have also worked with quite a few other people that have purchased them, they would be my first choice if buying new in this price range. I would recommend looking at the Acra 1640 TVS as well as the Precision Mathew's PM-1640TL (this is also available in a VFD model). If you go directly to Acra, the pricing is better, and also check PM/QMT. The VFD versions of these lathe all use a pressurized lubrication system, the stock do not. If you need a heavy duty version, then maybe the look at the Kent MXL-1740.

A few posting from the past.

I'm looking at getting a lathe and a mill. Looking at the Acra 1440TE, PM 1440TL and Kent RML1440. I have visited a tech school 2 weeks ago (4.5 hours one way) that had 4 used and 3 new ACRA 1440TE lathes in their shop. So I have actually got to see them. The tech school liked them so much they...

www.hobby-machinist.com

The machine was ordered mid December of 2017 from ACRA Machinery. The machine took a few weeks to arrive from Taiwan and was shipped to the port of LA, then onto Ranch Cucamonga where ACRA is located. The machine was then delivered to my location via flatbed. The machine sustained a fair amount...

www.hobby-machinist.com

My new ACRA lathe is home, now the job of getting it settled in, and cleaned up. It has been very tiring couple of days moving everything around, and cleaning up under things on wheels that never moved.

www.hobby-machinist.com

I will document the details of how I set up the PM-1660TL that I have backordered for 10 weeks or more. This will be my first 3 phase machine. I need to educate myself on how to power the machine from the 220V, 40A outlet which is located about 4 feet from the headstock. This 220V outlet is...

www.hobby-machinist.com

I was looking a little further and found the Sun Master ERL series. Anyone know if Sun Master has a US distributor? Or if there is a rebranded Sun Master ERL?

www.hobby-machinist.com

www.hobby-machinist.com

www.hobby-machinist.com

www.hobby-machinist.com

www.hobby-machinist.com

www.hobby-machinist.com

www.hobby-machinist.com

www.hobby-machinist.com

www.hobby-machinist.com

www.hobby-machinist.com

www.hobby-machinist.com