- Joined

- Mar 25, 2013

- Messages

- 4,614

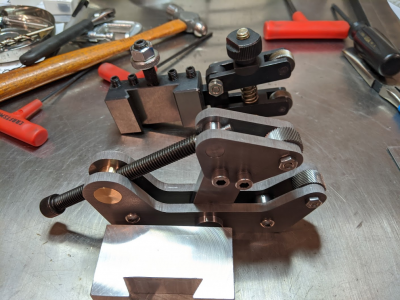

That would work if I could grind grooves into the axle. I may have a better idea. Drill the hole only partly through one arm. Then use a washer or plate to hold the axle in. That also leave nothing sticking out to interfere with the chuck.

Robert

Robert