- Joined

- Feb 8, 2014

- Messages

- 11,144

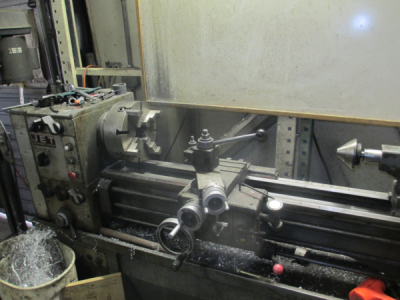

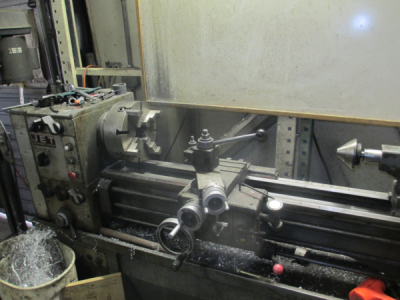

Last weekend my son informed me that it is time to put a DRO on the lathe. I guess he hasn't figured out what all those little numbers are for on the dials.  He has a short production run for a product he is developing so figured it would be easier to do it with a DRO. I suggested we just CNC the lathe, but he thought that would be overkill and make the lathe less useful. Mmmm OK.

He has a short production run for a product he is developing so figured it would be easier to do it with a DRO. I suggested we just CNC the lathe, but he thought that would be overkill and make the lathe less useful. Mmmm OK.  He's buying the DRO so we'll do it his way, I'll just spec it so it will be CNC compatible later.

He's buying the DRO so we'll do it his way, I'll just spec it so it will be CNC compatible later.

So this is the starting point. A basic Jet 1340GH.

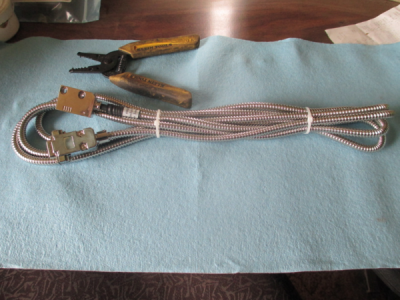

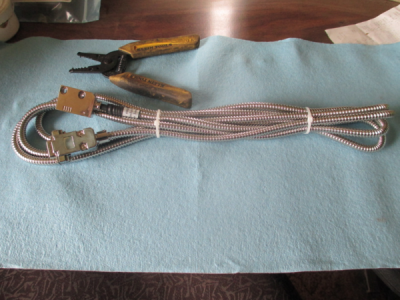

Since I have been experimenting Ditron products, I ordered one of their D100-2V readouts

And 2 of their DMR-200, 1um read heads, and 2 meters of magnetic tape. Should have all the pieces by Wednesday of next week.

See the test results of the DMR-200 read head here http://www.hobby-machinist.com/thre...le-replacement-vendor-spec.49299/#post-475210

Hmmm, does this mean that I can have 1 micron accuracy on my lathe now? Nah, I suppose not. Durn.

Nah, I suppose not. Durn.

I have never liked the idea of scales being exposed on a lathe, especially the cross slide scale, but have never seen a better way of doing it. Can't put it on the headstock side, it would be destroyed by something in no time. If you put the scale on the tailstock side of the cross slide, you lose some working clearance. Not acceptable in my book. I want the scale tape and read heads well protected and out of the way.

There is a better way.....I just haven't designed it yet. Stay Tuned..........

Stay Tuned..........

So this is the starting point. A basic Jet 1340GH.

Since I have been experimenting Ditron products, I ordered one of their D100-2V readouts

And 2 of their DMR-200, 1um read heads, and 2 meters of magnetic tape. Should have all the pieces by Wednesday of next week.

See the test results of the DMR-200 read head here http://www.hobby-machinist.com/thre...le-replacement-vendor-spec.49299/#post-475210

Hmmm, does this mean that I can have 1 micron accuracy on my lathe now?

I have never liked the idea of scales being exposed on a lathe, especially the cross slide scale, but have never seen a better way of doing it. Can't put it on the headstock side, it would be destroyed by something in no time. If you put the scale on the tailstock side of the cross slide, you lose some working clearance. Not acceptable in my book. I want the scale tape and read heads well protected and out of the way.

There is a better way.....I just haven't designed it yet.

Stay Tuned..........

Stay Tuned..........