- Joined

- Feb 12, 2021

- Messages

- 34

Good day,

I'm getting into home machining as a way to self teach myself. I'm hoping to start a home based gunsmithing and small machining shop, as I'm partially handicapped and working for others isn't feasible.

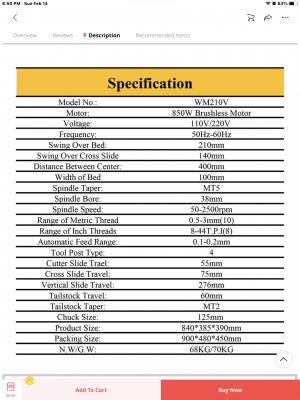

I came across this machine on Alibaba, and I'm looking for opinions. I've already reached out to the manufacturer about setting it up to make imperial threads.

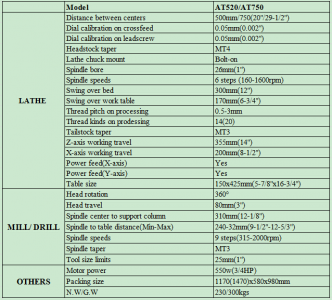

Here's the specs -

I don't think I can post a link as I'm a brand new member.

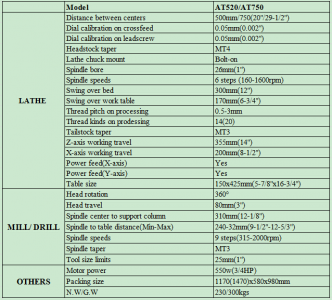

I'm also wondering what you guys (and gals) think about these combo units in general? Like I said, this machine is to teach myself and my wife about machining. The things we make on it won't need 0.00001 precision, as long as it can make decent practice projects.

All thoughts, opinions and comments are welcome. If this isn't a good way to go, I have a very decent looking lathe picked out to start.

Thanks,

Ken

I'm getting into home machining as a way to self teach myself. I'm hoping to start a home based gunsmithing and small machining shop, as I'm partially handicapped and working for others isn't feasible.

I came across this machine on Alibaba, and I'm looking for opinions. I've already reached out to the manufacturer about setting it up to make imperial threads.

Here's the specs -

I don't think I can post a link as I'm a brand new member.

I'm also wondering what you guys (and gals) think about these combo units in general? Like I said, this machine is to teach myself and my wife about machining. The things we make on it won't need 0.00001 precision, as long as it can make decent practice projects.

All thoughts, opinions and comments are welcome. If this isn't a good way to go, I have a very decent looking lathe picked out to start.

Thanks,

Ken