- Joined

- Aug 17, 2018

- Messages

- 57

Hello everyone,

I have just purchased and my brand new to me mini lathe has arrived, it has come with a selection of tools, of which I know nothing.

I've tried reading up a little about it but I'm still lost regarding which tool is used for what.

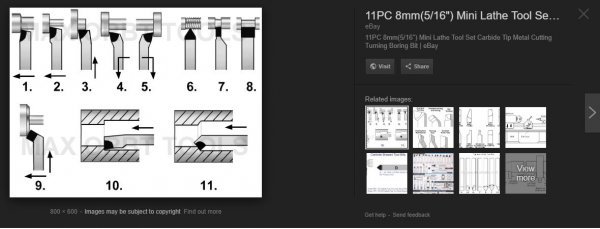

I'm attaching an image with all of the tools laid out separated by left and right with a few in the middle I'm not sure about...

Could someone tell me which tool is for what?

I have just purchased and my brand new to me mini lathe has arrived, it has come with a selection of tools, of which I know nothing.

I've tried reading up a little about it but I'm still lost regarding which tool is used for what.

I'm attaching an image with all of the tools laid out separated by left and right with a few in the middle I'm not sure about...

Could someone tell me which tool is for what?