It looks like there are two leads going into the motor from each of the line connections.

One will be to the start windings, the other to the run windings.

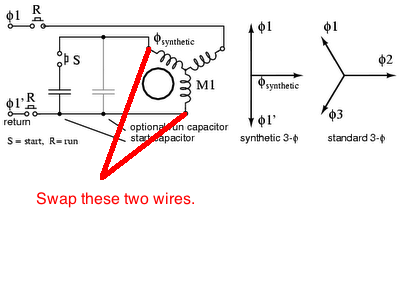

Switch one set of the leads going into the motor. You can determine which of the leads going into the motor are a set by measuring with an ohm meter; the sets will have a low resistance, the non-sets will have a high resistance.

To try to make it clearer, the power comes in on the red and black wires.

There are two wires connected to the red wire (in the yellow wire nut). Label one A and the other B.

There are also two wires connected to the black wire (in the red wire nut). Label one C and the other D.

Use an ohm meter to measure the resistance between A and C, B and C, A and D, and B and D.

Two of the readings should be low; the other two should be high.

If A and C (and B and D) are low, move A to the black wire and C to the red wire.

If B and C (and A and D) are low, move B to the black wire and C to the red wire.

If none of the pairs are low, or if they're all low, (or if you don't really have two wires going to the motor from the red and black wires) then I have no idea what's going on with the motor.

Good luck!

Carl

One will be to the start windings, the other to the run windings.

Switch one set of the leads going into the motor. You can determine which of the leads going into the motor are a set by measuring with an ohm meter; the sets will have a low resistance, the non-sets will have a high resistance.

To try to make it clearer, the power comes in on the red and black wires.

There are two wires connected to the red wire (in the yellow wire nut). Label one A and the other B.

There are also two wires connected to the black wire (in the red wire nut). Label one C and the other D.

Use an ohm meter to measure the resistance between A and C, B and C, A and D, and B and D.

Two of the readings should be low; the other two should be high.

If A and C (and B and D) are low, move A to the black wire and C to the red wire.

If B and C (and A and D) are low, move B to the black wire and C to the red wire.

If none of the pairs are low, or if they're all low, (or if you don't really have two wires going to the motor from the red and black wires) then I have no idea what's going on with the motor.

Good luck!

Carl