- Joined

- May 26, 2015

- Messages

- 762

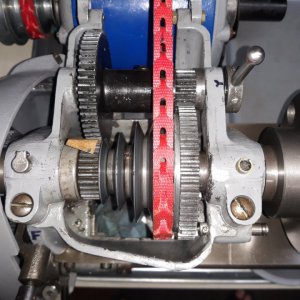

Anyone had any experience with cleaning oil deposits from the link belts I'm using? I notice that my belt is starting to slip at times when cutting. If it were a "normal" fan belt I would have used mineral spirits on a rag but with a link belt it wants to grab that rag right out of my hand and into the pulleys! LoL