- Joined

- Sep 21, 2017

- Messages

- 117

Hello all,

I think that I will have a go at the shaft removal process today. I won't likely get it all done, but I will get a good start on it.

First, I am heading out into the woods, to swap out my SD cards on a couple of game cameras. I am studying a family of coyotes. The temperature, factoring the wind chill, is - 40° !!!Coincidentally, it is the same temperature when converted to Fahrenheit. I'll turn the heat on in the shop, before I go.

I'll be back later on this afternoon, with some progress.

Brian

I'll be waiting for the update.

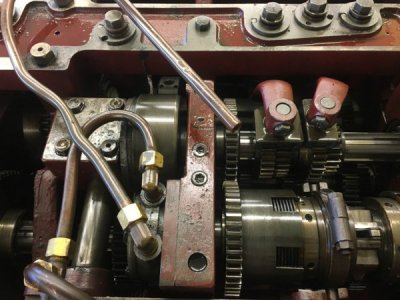

I really enjoy seeing how you get along with this project. I hope the gear issue doesn't discourage you, it's going to take considerable effort to find a solution without a good used parts source.

I really enjoy seeing how you get along with this project. I hope the gear issue doesn't discourage you, it's going to take considerable effort to find a solution without a good used parts source. And good luck on the coyotes. My parents had trouble with coyotes getting into the baby lambs maybe 10-15 years ago. We have Eastern Coyotes around here, very clever and VERY pervasive. It was sooooo frustrating to see them kill for sport. It would have been different to see them eat their kill b/c they're hungry, but infuriating to see them kill half a dozen and only eat the tongues...