- Joined

- Nov 16, 2014

- Messages

- 56

Hi guys.

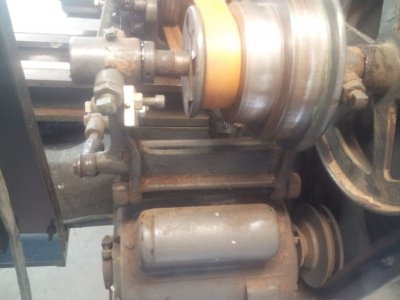

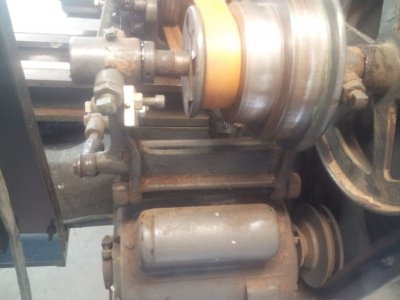

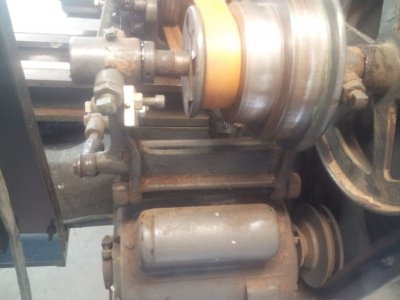

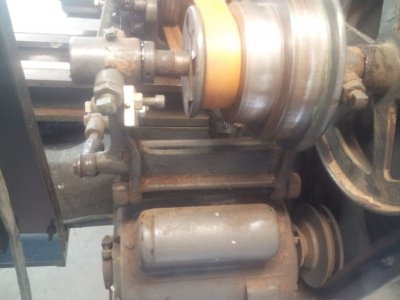

I have an 04TLC-700 with a broken bearing support on the countershaft bracket. A prior owner made a temporary repair with a bolted-on doubler over the break.

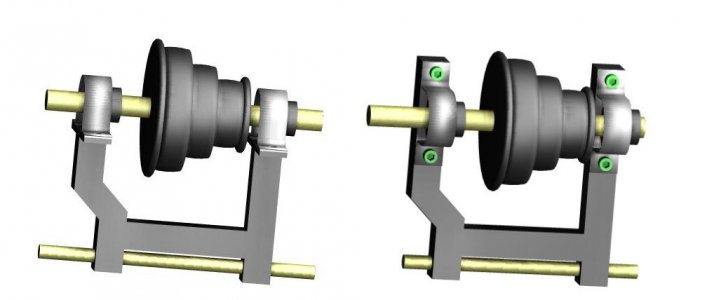

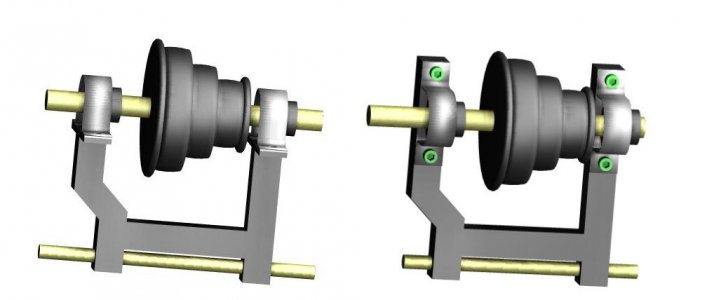

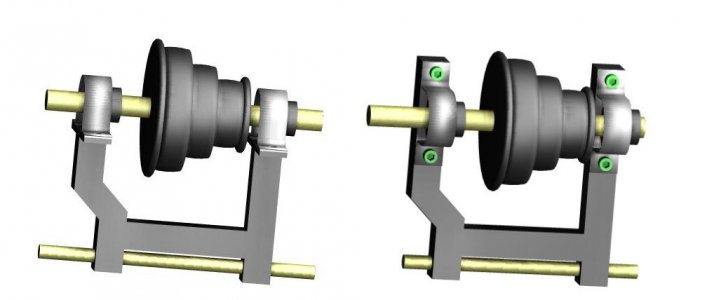

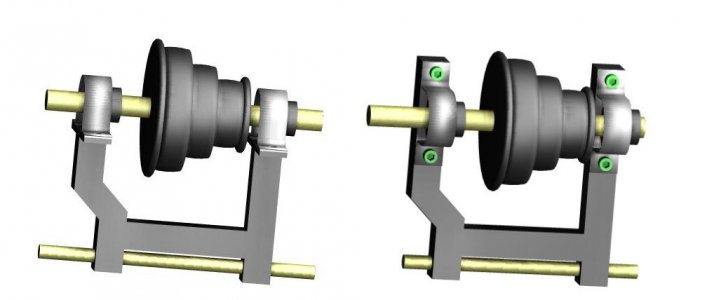

I'd like to make a more permanent repair, but I haven't been able to find another countershaft bracket (LA-302). So I'm contemplating fabricating one. Here is a sketch of a couple of options using pillow blocks for the countershaft bearings.

The one on the left looks more like the OEM part, but I feel the one on the right would be easier to fabricate.

I'd welcome some comments on this approach, and I wonder if someone can tell me how critical the alignment is for the flat belt pulleys.

I can make adjustments with shims and slotted mounting holes, but I'm wondering if there's a need for some kind of screw adjustment, similar to the OEM setup.

Thanks in advance for any feedback.

regards,

Leon

I have an 04TLC-700 with a broken bearing support on the countershaft bracket. A prior owner made a temporary repair with a bolted-on doubler over the break.

I'd like to make a more permanent repair, but I haven't been able to find another countershaft bracket (LA-302). So I'm contemplating fabricating one. Here is a sketch of a couple of options using pillow blocks for the countershaft bearings.

The one on the left looks more like the OEM part, but I feel the one on the right would be easier to fabricate.

I'd welcome some comments on this approach, and I wonder if someone can tell me how critical the alignment is for the flat belt pulleys.

I can make adjustments with shims and slotted mounting holes, but I'm wondering if there's a need for some kind of screw adjustment, similar to the OEM setup.

Thanks in advance for any feedback.

regards,

Leon